Odoo Manufacturing - Improved Operational Efficiency

To illustrate the brief overview & history of manufacturing, it began as a hand-made procedure. It started as a hand-made process to outline the brief history of development. The raw materials were processed into useful products by qualified laborers. The intervention of devices and mechanics was minimal. In order to produce products that were useful to consumers, basic tools and human labor were then used to increase the value of the raw materials. Finished products are always sold at a higher value than the sum of raw materials, taking into account the production of labor.

In the 19th century, with rising buyers, finished goods were more in demand. It demanded mass production. Thus, production began to be mechanized. This lowered labor spending and increased the output of goods. Mass processing required labor division and mechanization to maximize labor productivity. With the industrial revolution, assembly-line production and industrial productivity increased geometrically. The definition of production and manufacturing has changed dramatically.

With the rising population and changing social and economic systems, the need and demands keep growing. The greater the growth, the greater the demand. For the growth of a company, improving the productivity of factories and production units is indispensable. Although the first step to improving production efficiency was mechanization, today the shift is towards automation.

Assembly line production

In their production phase, most mass manufacturing units have switched to assembly lines. This enables manufacturers to produce in a predefined sequence the parts of the finished product and assemble them step by step to produce the final product. In many sectors, the process is one that has found appeal.

Production line

In comparison to the assembly line, the production line does not require the assembly of components to form a new product, but rather the packaging of raw materials into finished products. In food manufacturing, this is widely used.

Production has advanced so far today that even quality controls, product life management, maintenance, etc. are involved. Every day, the production units are improving their game. More and more has been added to the development and the management of this quality of the system has its own challenges. The manufacturing unit is automated by most businesses to preserve the system's productivity.

Odoo Manufacturing

To ensure maximum customer satisfaction and smooth production, the Odoo manufacturing platform regulates the multiple functions of the manufacturing unit. The software is integrated with other units, such as:

Purchasing, "Buying"

The PLM

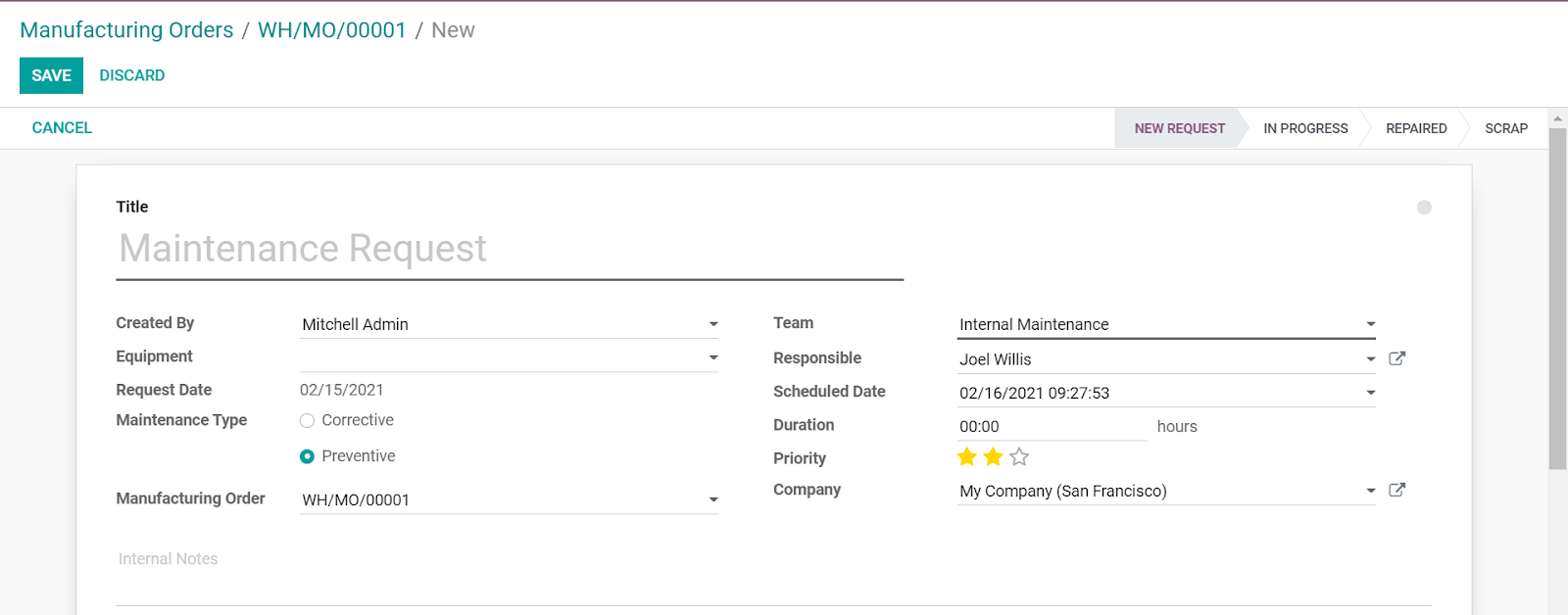

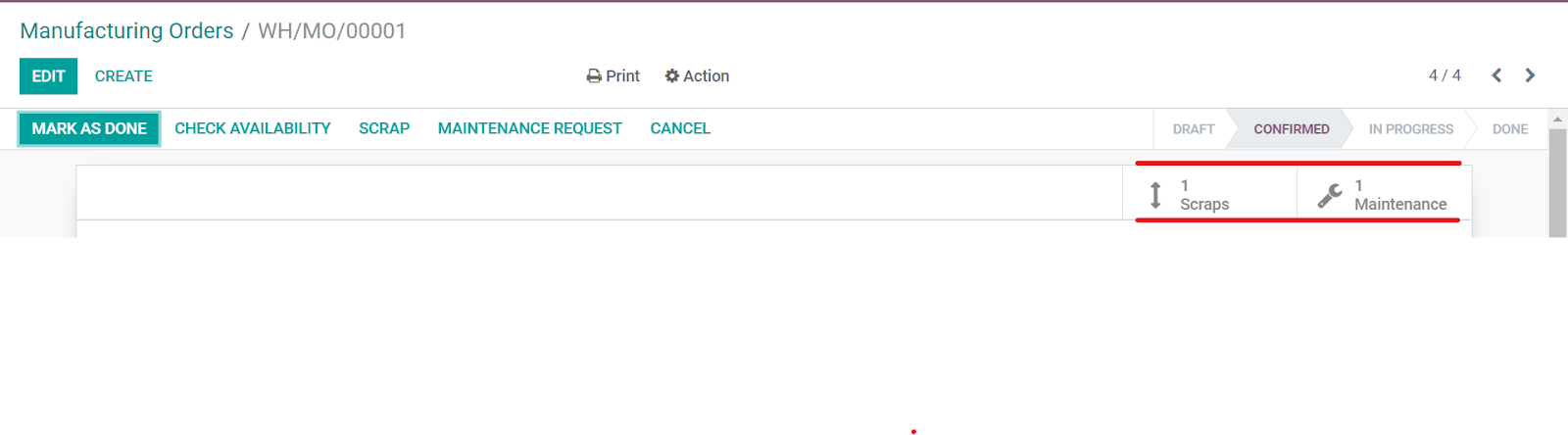

Repair and maintenance

Quality

There are these add-on modules in the manufacturing module that boost the functionality.

With a single manufacturing unit or multiple work centers, the Odoo Manufacturing module may run. We should ensure that the work centers in the configuration are unchecked and set up and create a different manufacturing order in the case of a single manufacturing unit.

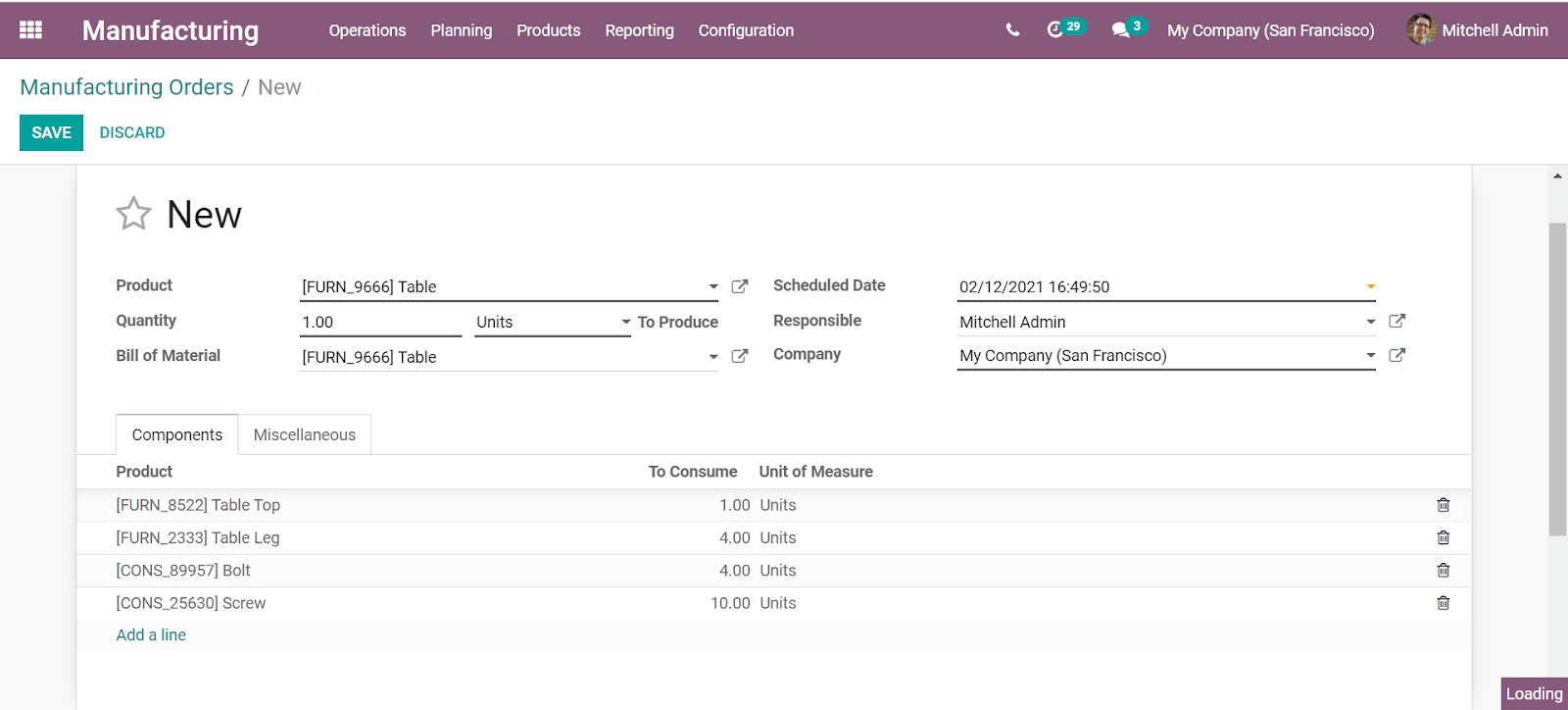

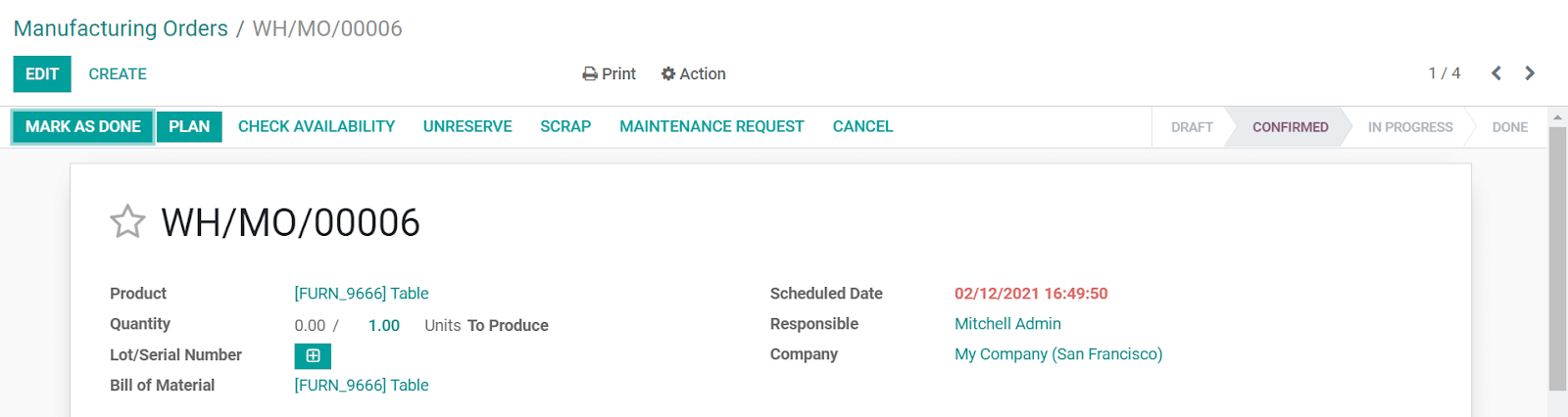

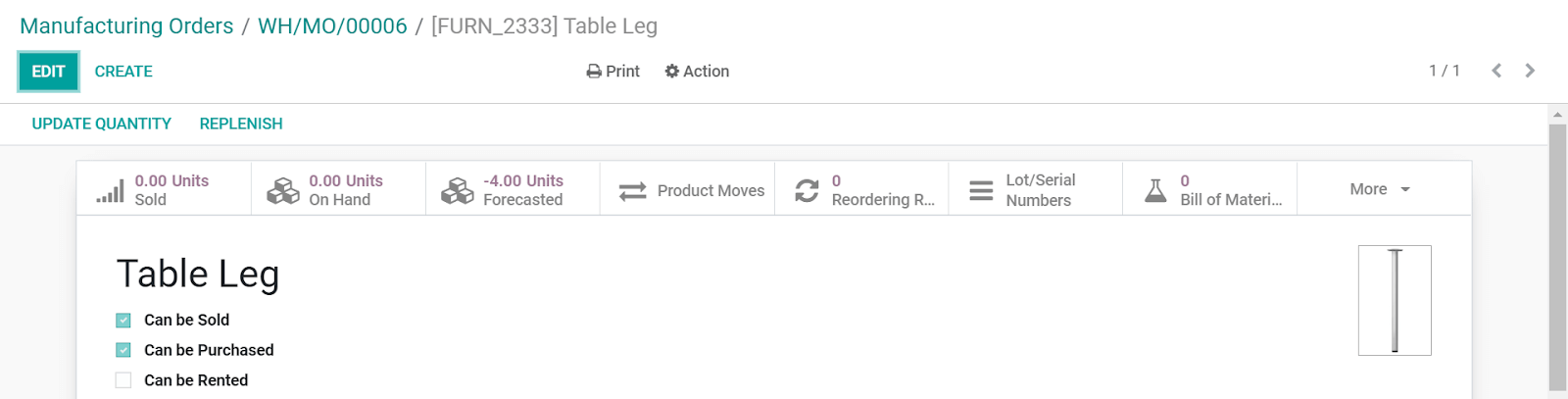

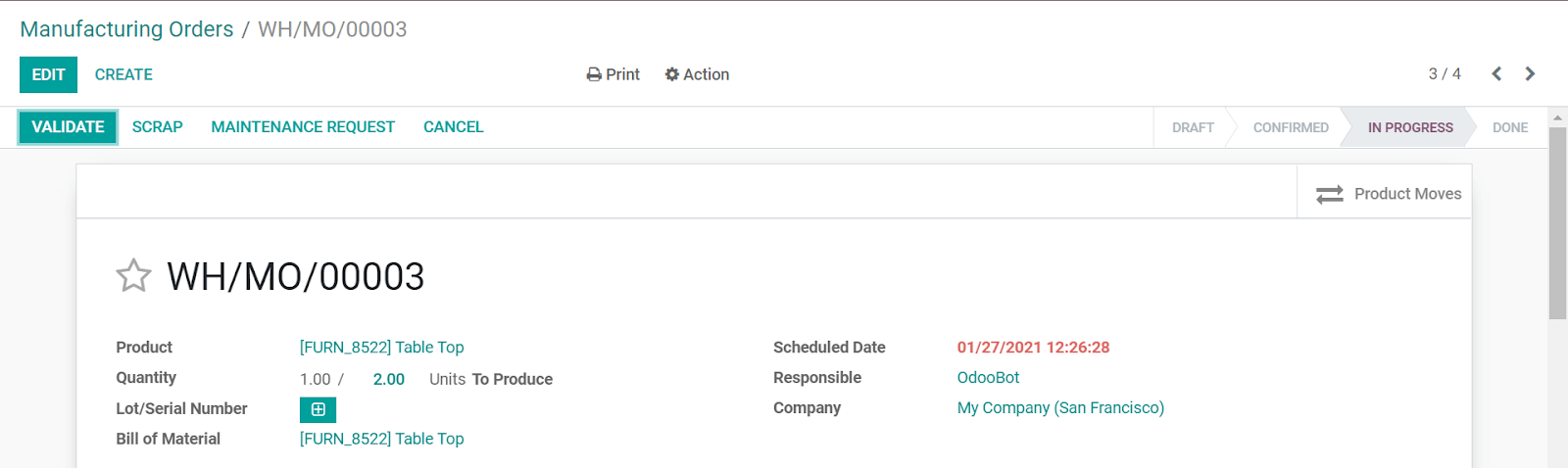

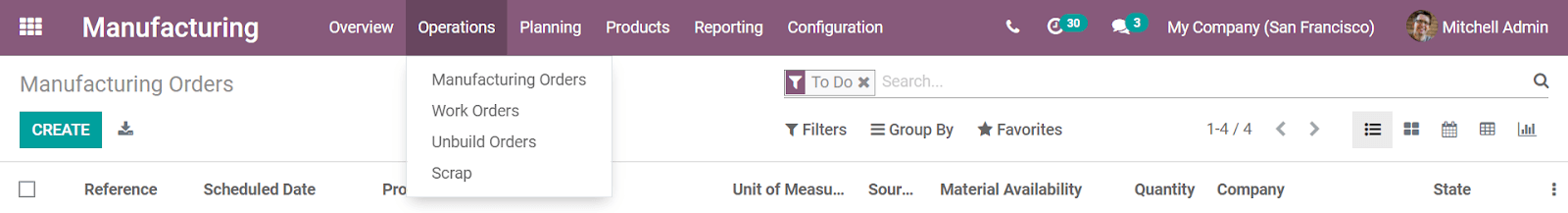

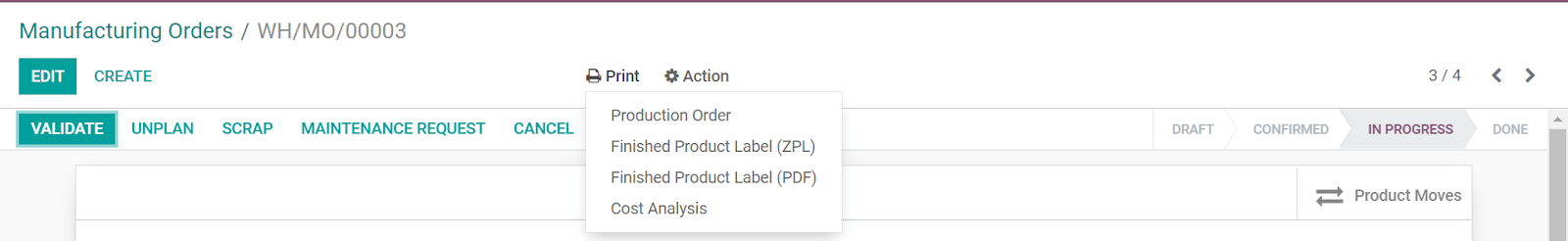

Creating a Manufacturing Order

From the dashboard, we can create a new order and edit the order details.

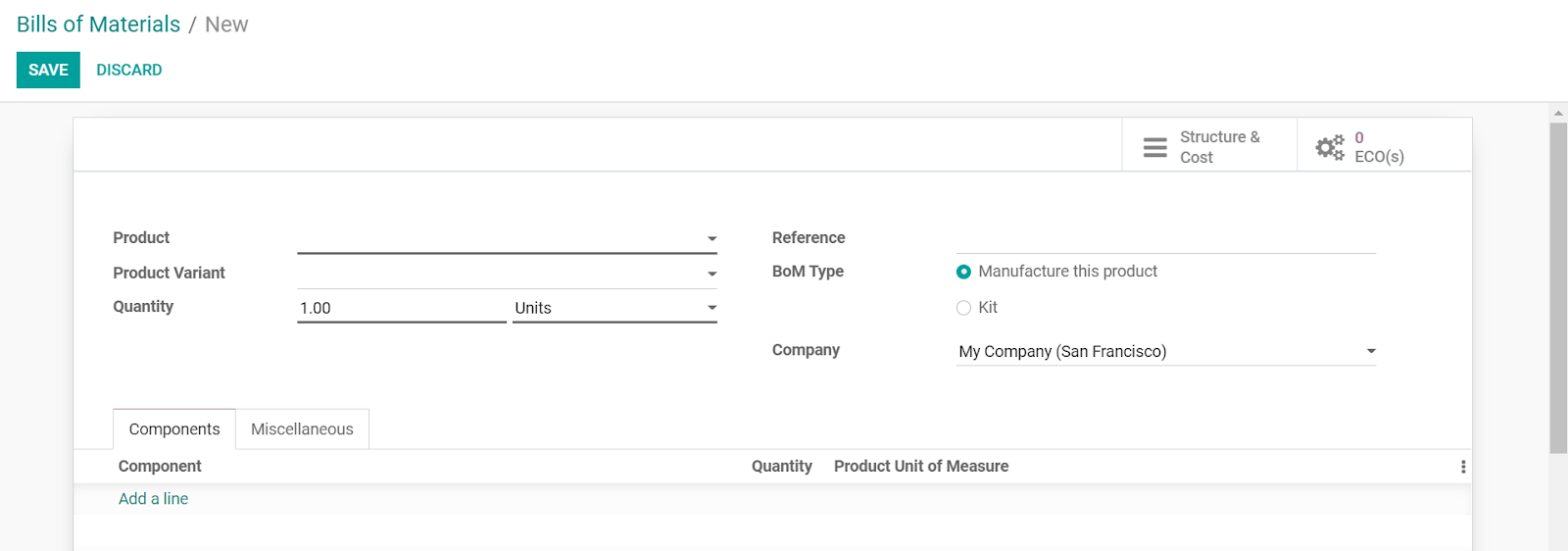

Create Bill of Materials

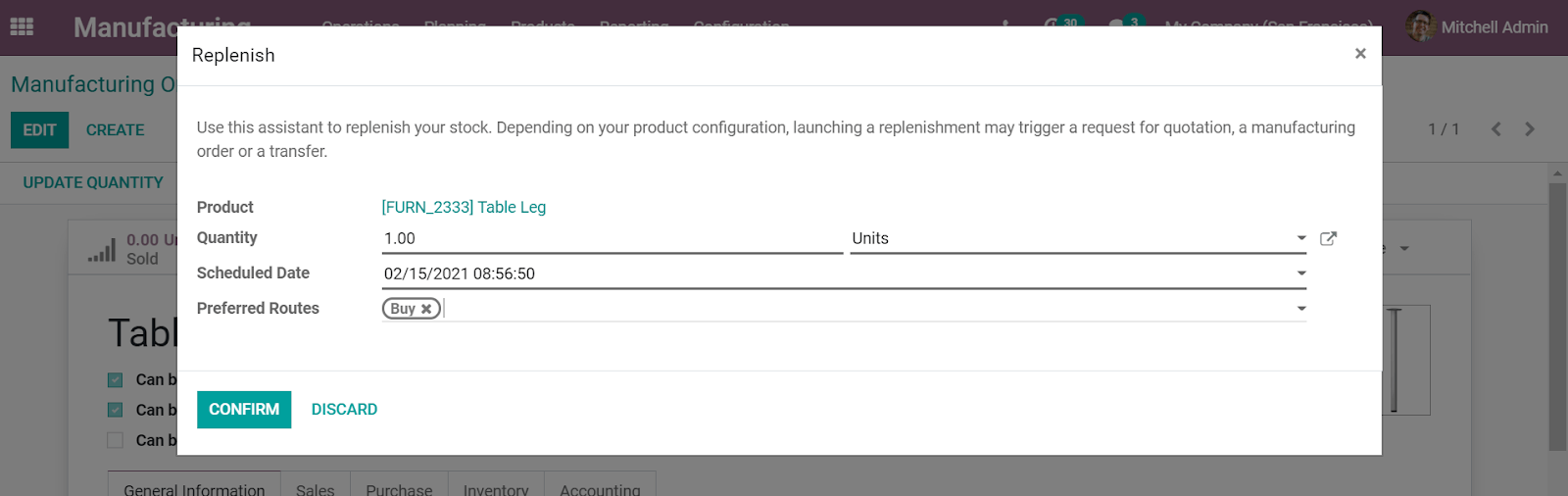

The material bill can be created under the menu of the products. We may describe & define a product, a variant, and the number of units in the BoM menu. The type of BoM can choose between this product and Kit manufacturing. While establishing production order and during inventory transition, the BoM style kit will break the items into components.

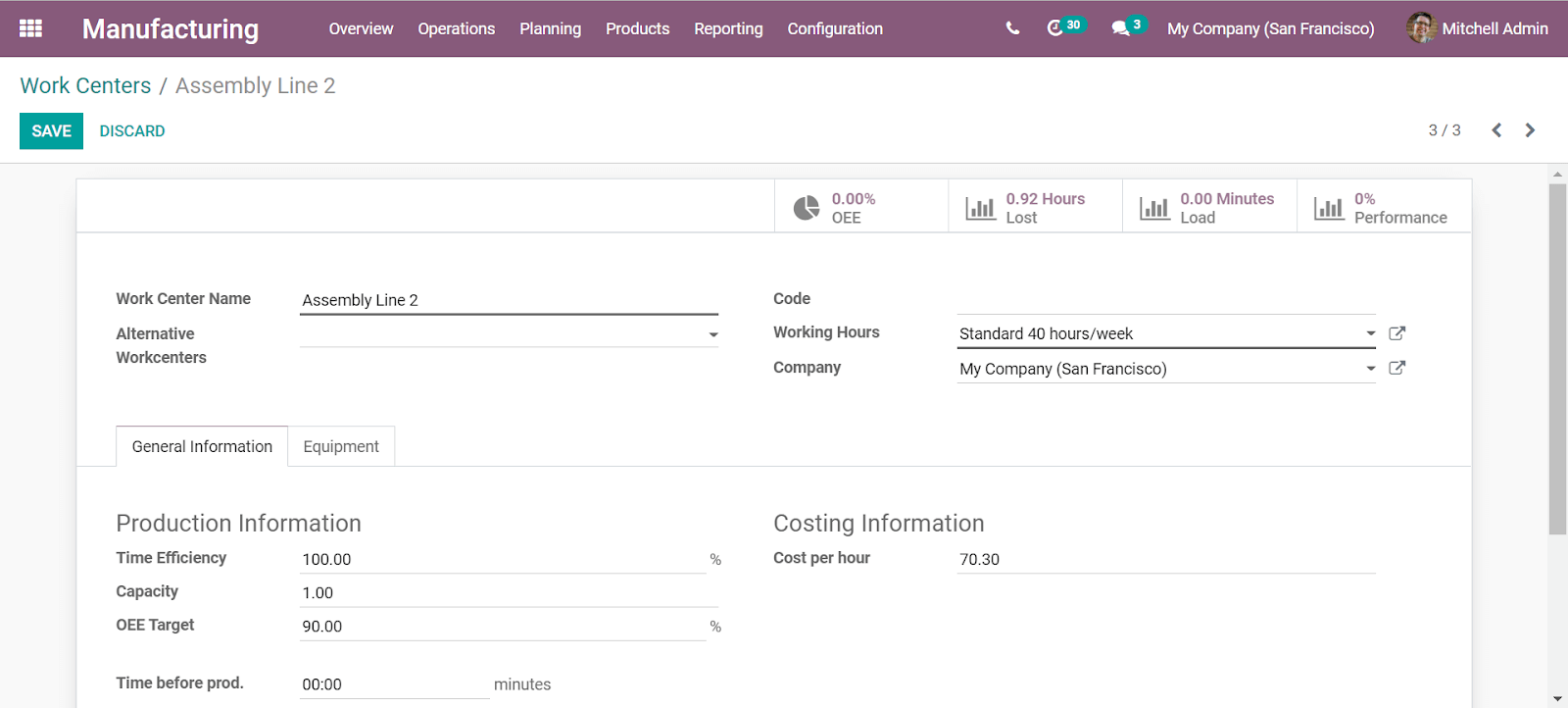

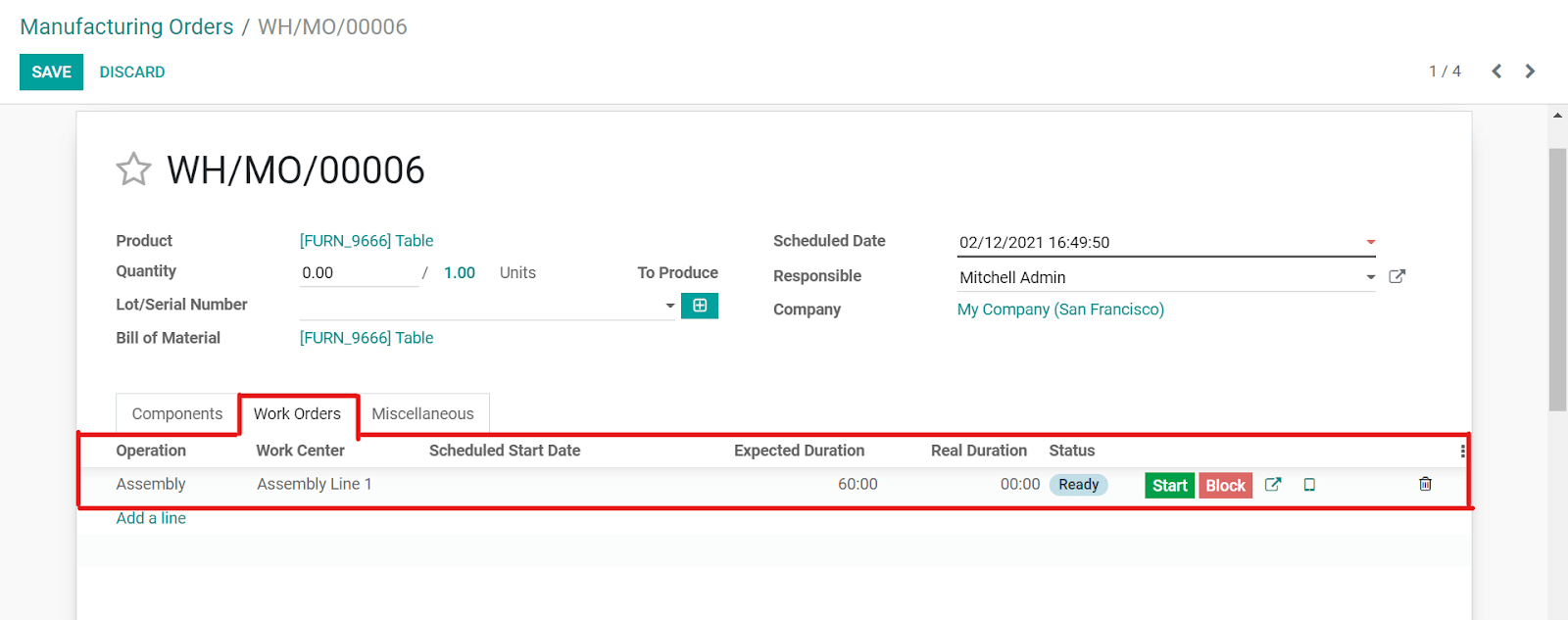

Manufacturing with work centers

Conclusion:

Conclusion:

Odoo Manufacturing - Improved Operational Efficiency

At ERP Cloud, we are an ERP Application Development Company with the goal of optimizing the potential of upcoming technology for businesses. For every business size, market, framework, platform, and use case, we develop Cloud-based models. Integrated with WFM, SCM, CRM, HRM, and accounting services, we develop ERP applications. Speak to our professionals now and use our all-in-purchase Custom Odoo ERP implementation software for the manufacturing industry!

This is a summary of the creation of manufacturing orders for Odoo manufacturing. You can visit our Contact Us Page or drop us a line at sales@erpxcloud.com for additional clarification and a comprehensive overview of the module.

50,000+ companies run Odoo to grow their businesses.

Join us and make your company a better place.

Odoo Manufacturing - Improved Operational Efficiency