Odoo 15 BOM

The list of components or raw materials needed to make a product is known as a bill of materials. Manufacturers typically create a bill of materials prior to beginning the manufacturing process. Instructions on how to put the parts together are frequently included in the bill of materials. There are various ways to manufacture the same product, thus you can create multiple bills of material for it. To maintain precision in manufacturing, it is essential to create an exact list of the raw materials used to make a product. The Bill of Materials, or BOM, is, in a nutshell, the core component of any manufacturing operation. The Bill of Materials (BOM) creation platform in Odoo 15 is specifically designed for your manufacturing and sales processes.

This article will discuss how to create a Bill of Materials in Odoo 15.

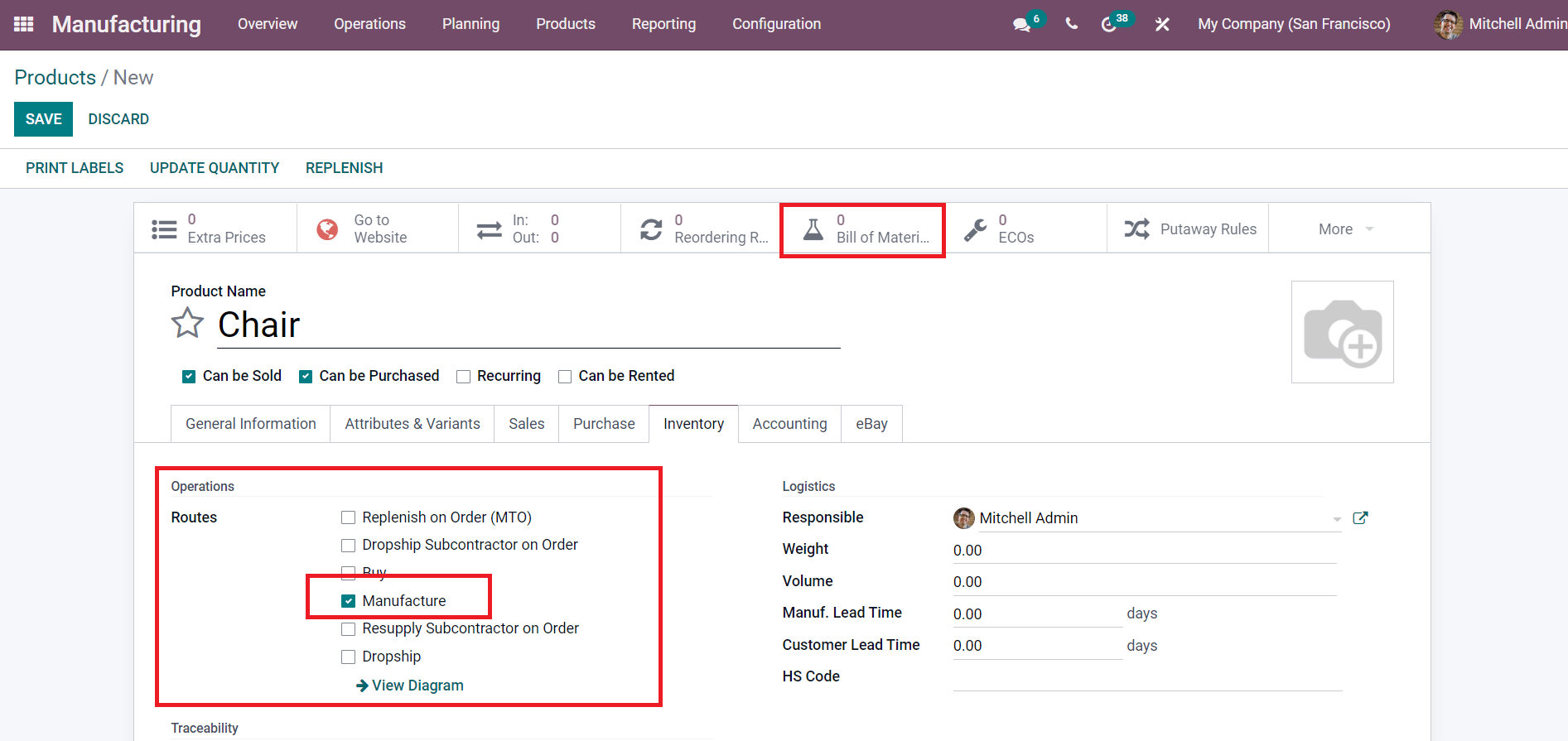

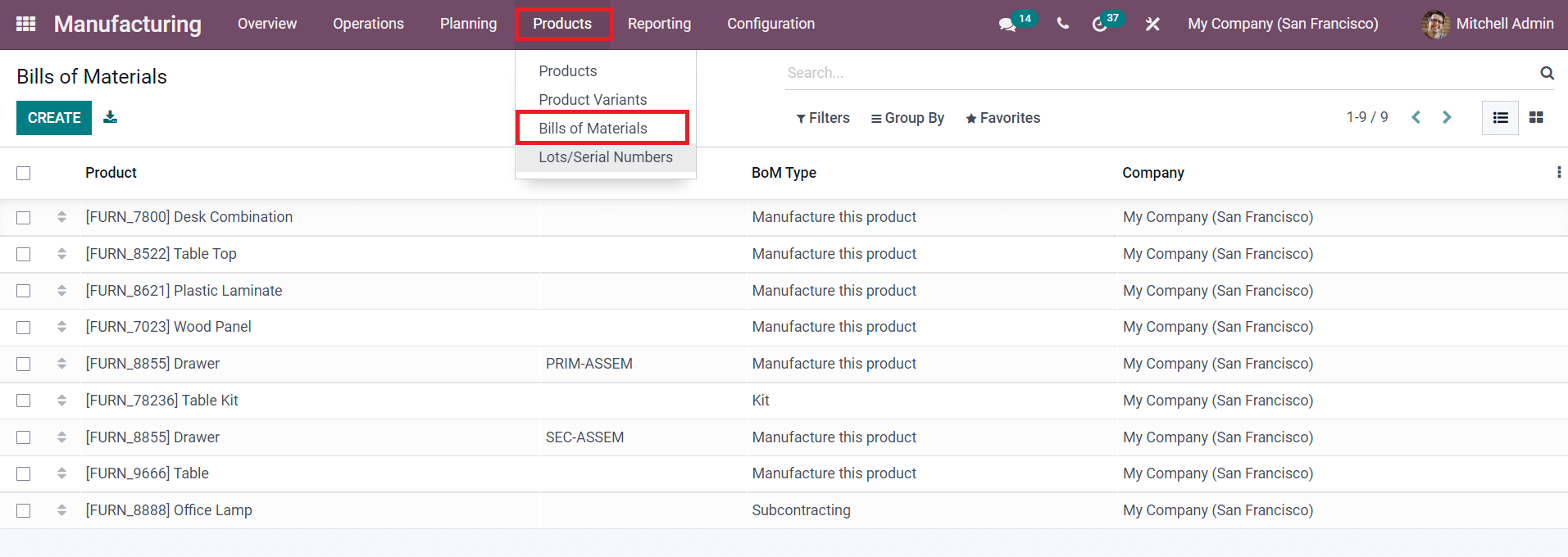

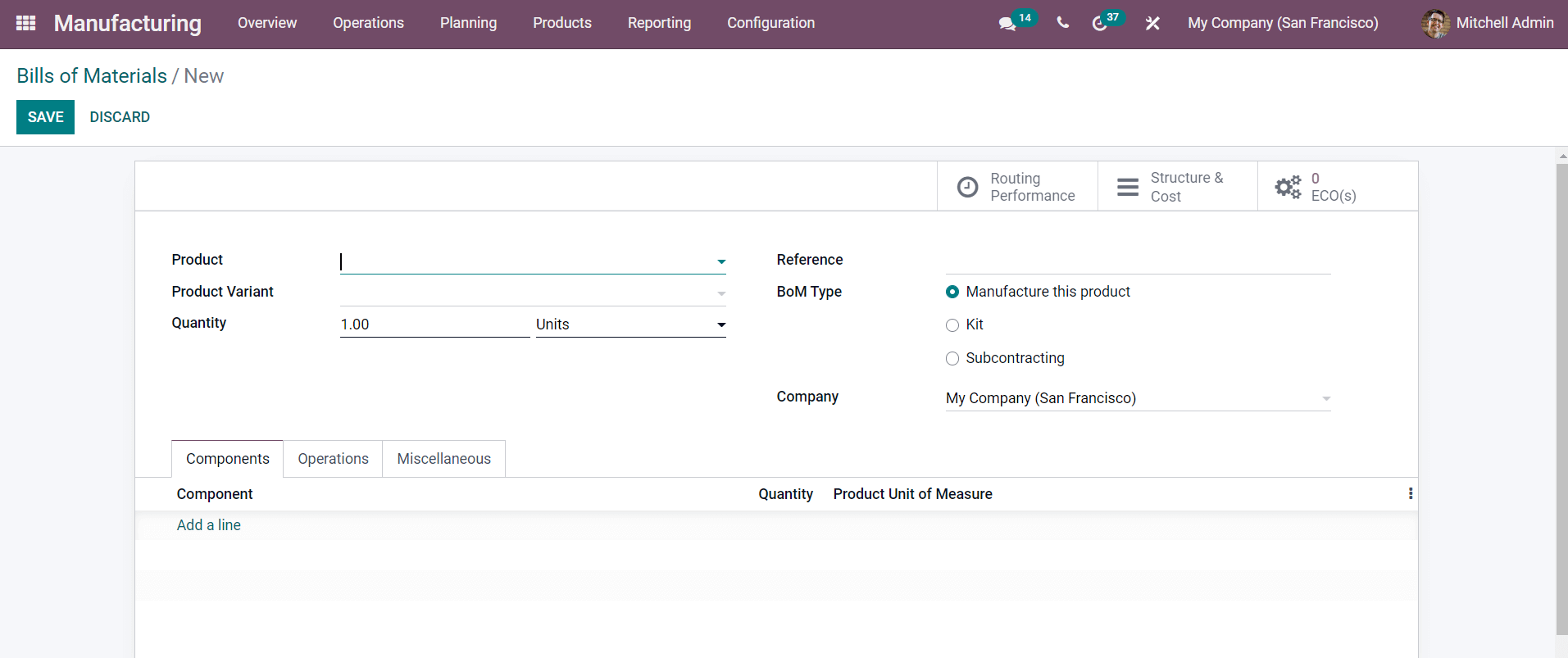

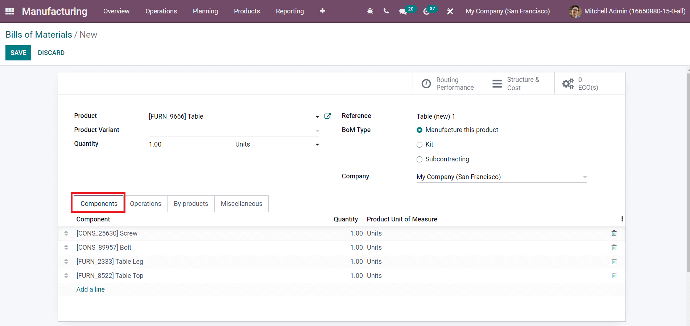

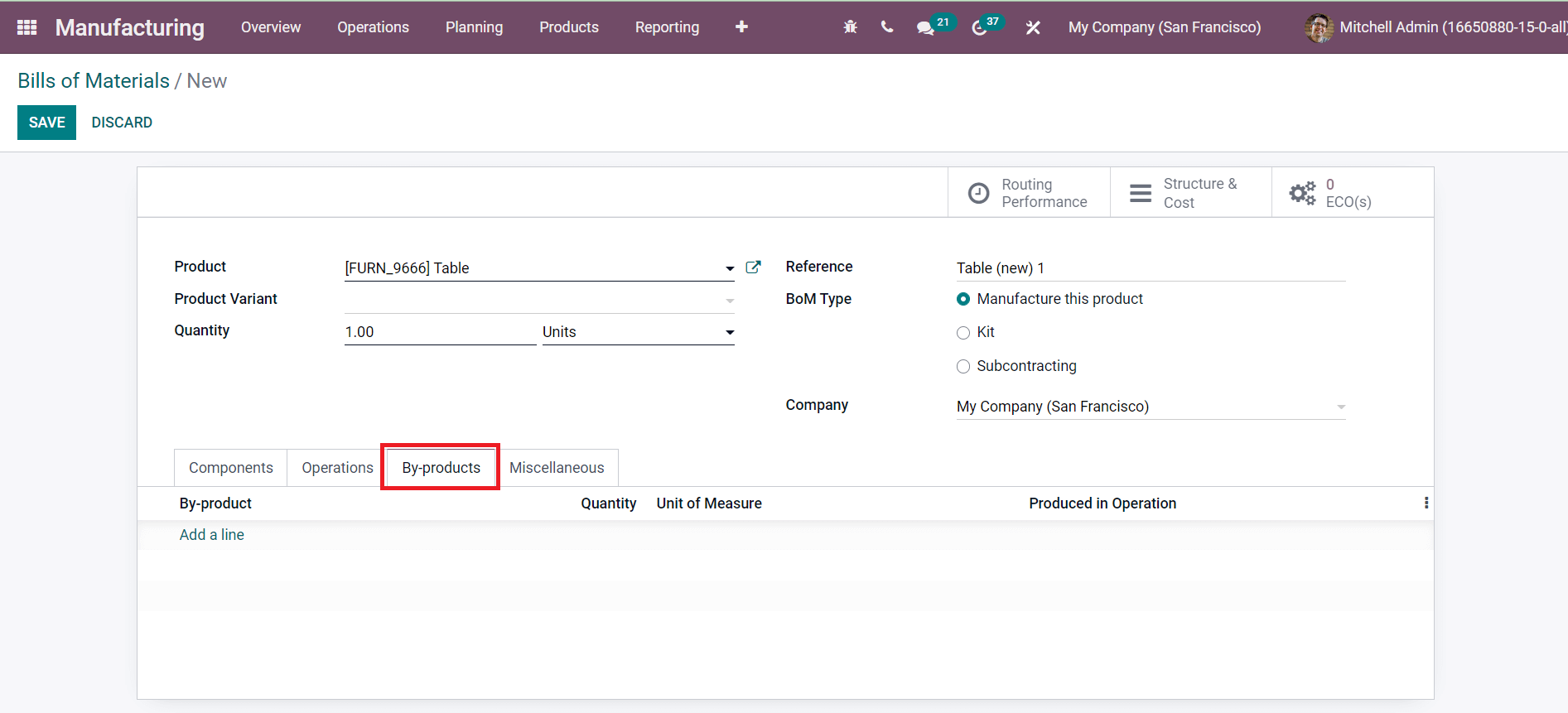

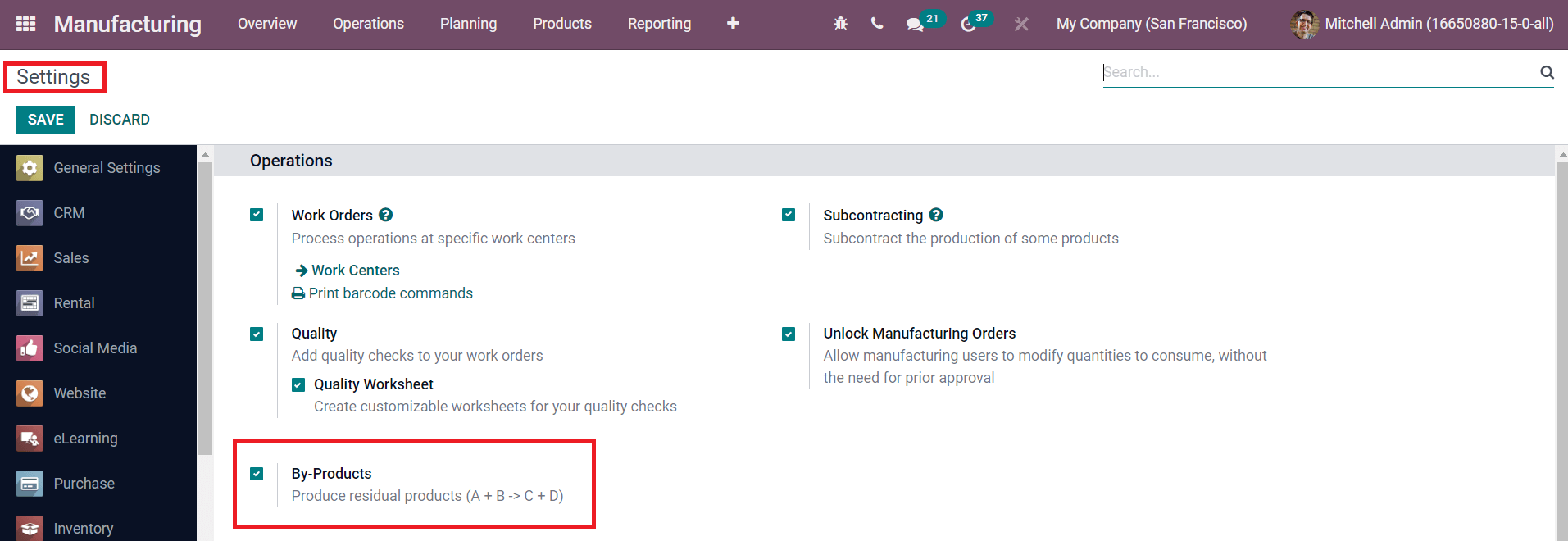

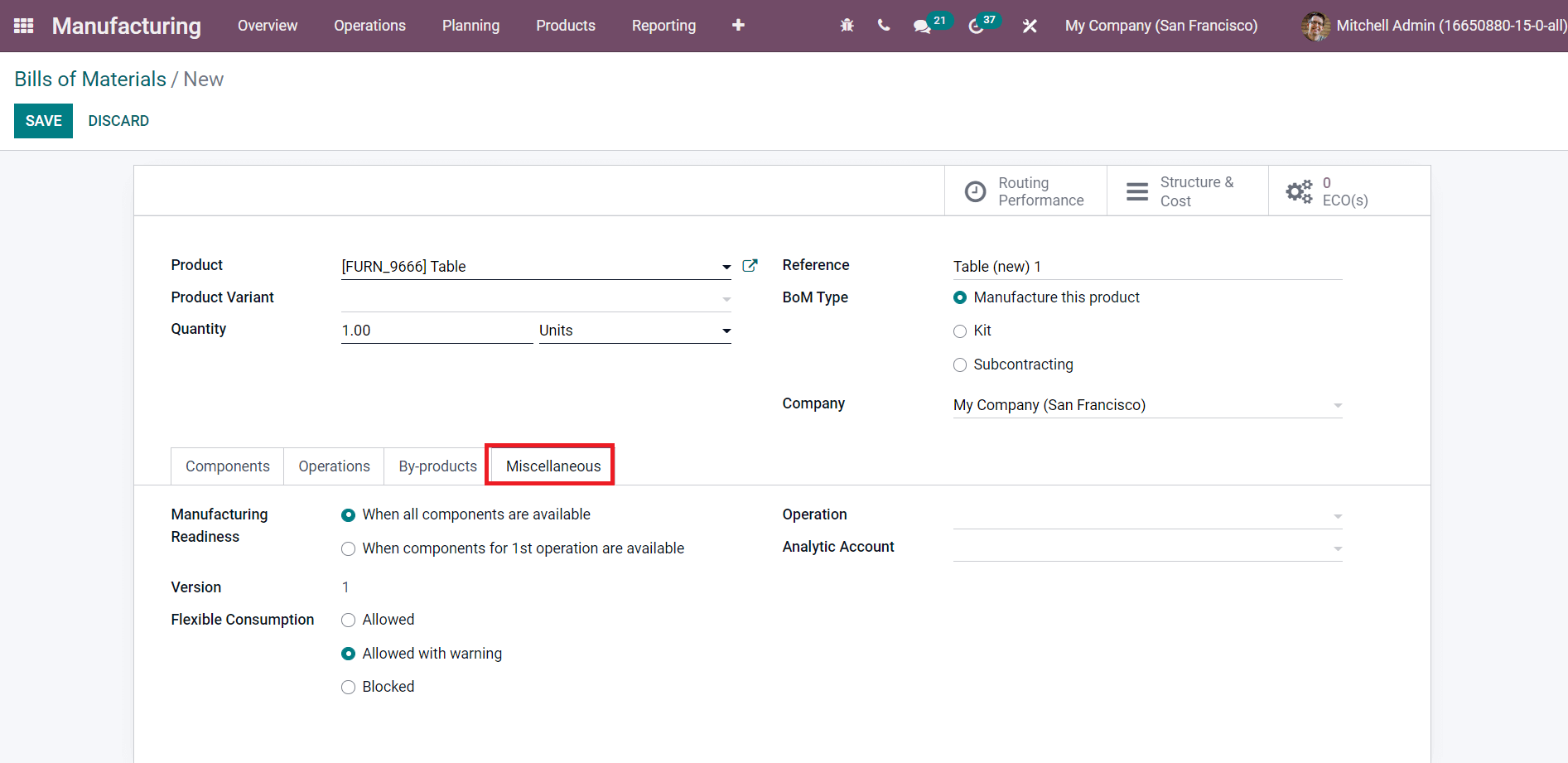

You can set up the matching product in your database and the Bill of Material setup before starting the production process. From the Odoo main dashboard, select the Manufacturing module. You can configure the product and enter the information needed for its manufacture in the Product Configuration window. Since we will be manufacturing this product, you can select Manufacture as the Route of Operations under the Inventory tab.

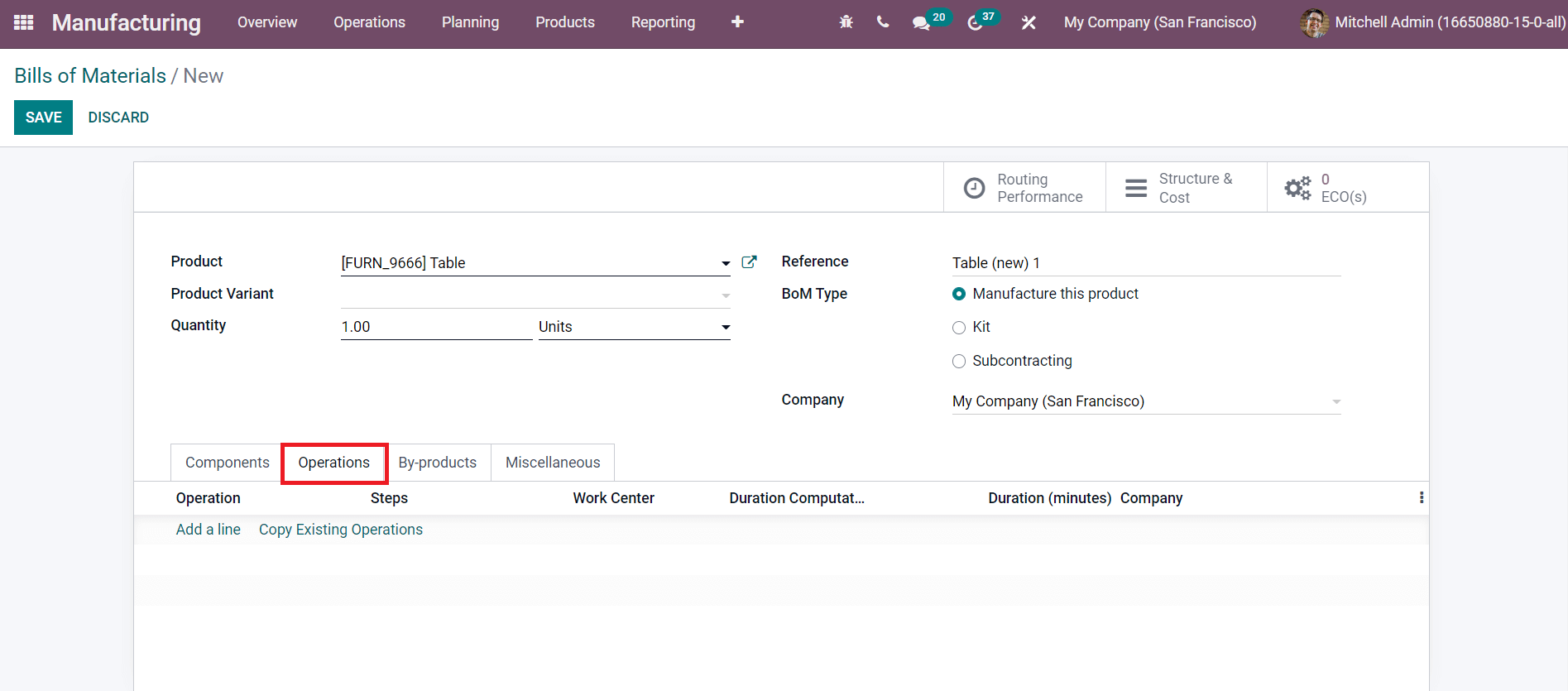

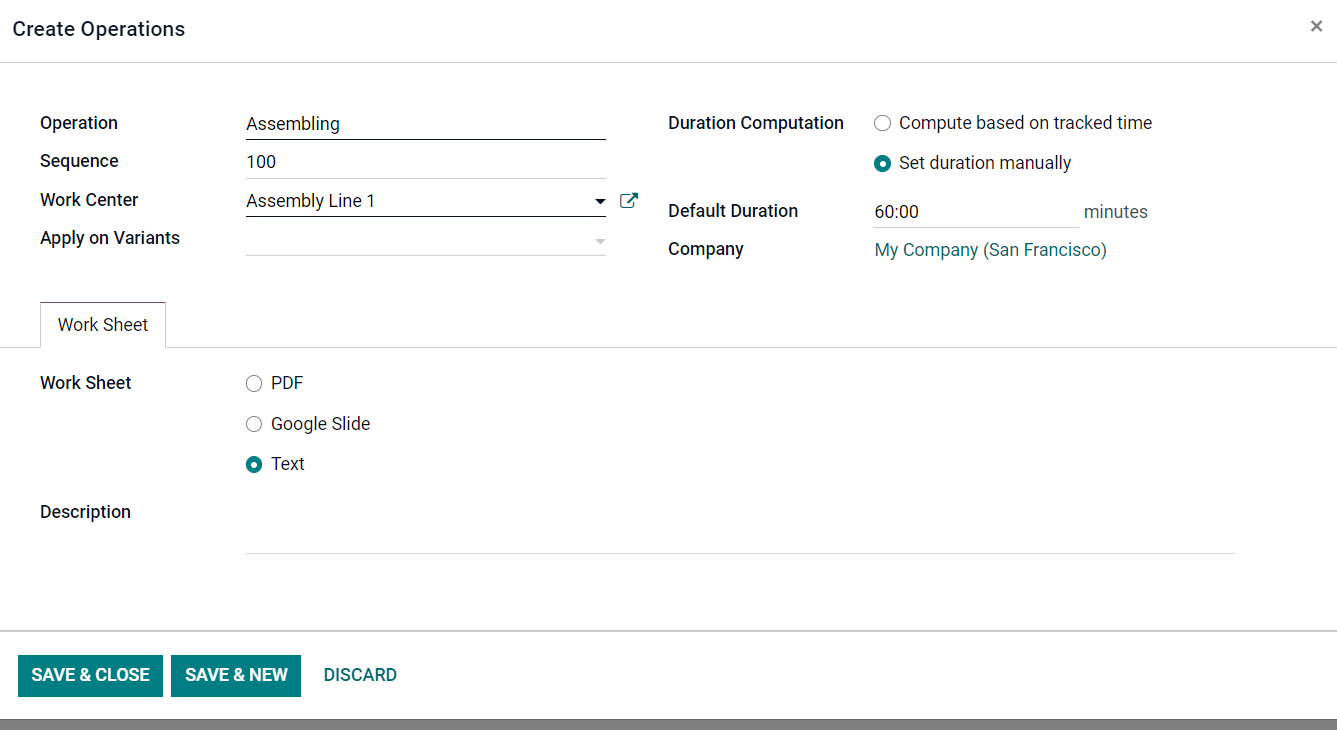

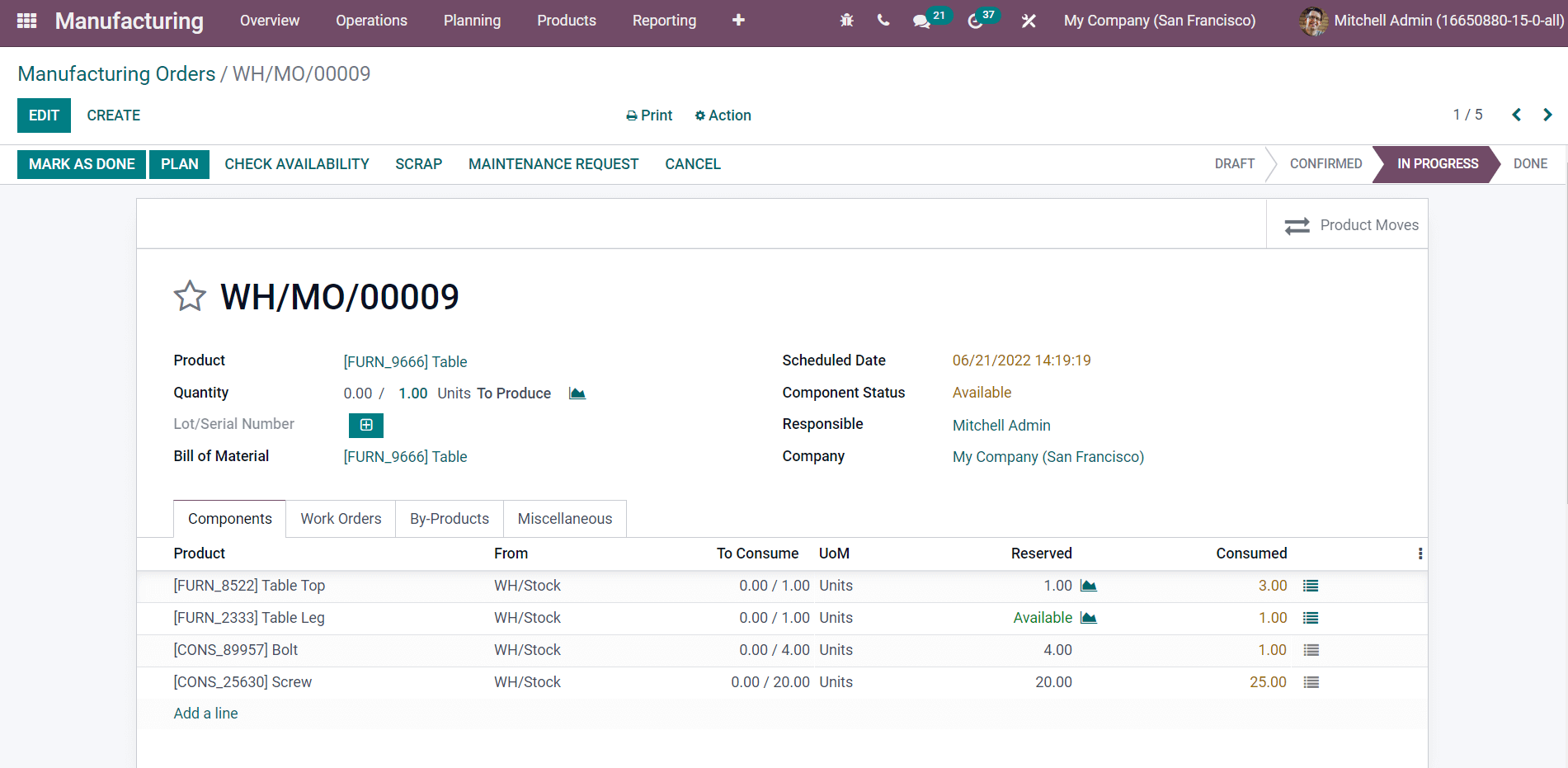

Under the Operations tab, you can set the Operations to run on several workstations. You can specify each step needed to finish making the Table by using the Add a Line button.

Conclusion: Odoo 15 BOM

In this article, we discussed how to quickly set up the Bill of Materials for the product's manufacture using the Odoo 15 Manufacturing module.

For more information about the Odoo 15 Inventory Module, please contact us at sales@erpxcloud.com

ERP Cloud LLC, an Odoo Certified Partner, offers a variety of Odoo ERP services, including Odoo Implementation, Odoo Customization, and Odoo Integration, based on individual business requirements.

Our specialized team of Odoo professionals is ready to create and implement the best solutions for your businesses to achieve maximum outcomes in terms of leads, sales, and money.

Odoo 15 BOM