Odoo 15 ERP to Manage Your Manufacturing Business

Planning and controlling your operations on a regular track in a manufacturing organization are two sides of the same coin. Each work performed in a manufacturing business, such as production operations, labor management, machine control, and other activities, will be chaotic if the manufacturing business is not monitored or controlled in a coordinated manner. As a result, we must be inquisitive about using the ideal ERP program for overall manufacturing business monitoring. The Odoo 15 is a dynamic and adaptable solution for managing your manufacturing company.

The Odoo V-15 improves manufacturing processes, encourages industrial automation, and allows you to manage and strategize your operations from a single platform. In a manufacturing environment, all work is completed in accordance with the company's production order. The firm, according to it, follows up on the job order, manufacturing, and other activities. The Odoo ERP solution may be used to efficiently do these tasks. As we all know, establishing an effective ERP improves the operations in a manufacturing unit while also lowering the cost. It causes you to make a minor financial adjustment. In a manufacturing firm, Odoo also forces you to steer your business by a chosen timeline and prioritize processes.

However, the manufacturing industry involves a number of time-consuming operations that cannot be rectified manually. In this case, the ideal approach is to deploy a superior ERP tool, such as Odoo V-15. The Manufacturing module in Odoo 15 may focus on the manufacture company by managing different activities such as arranging manufacturing orders, processing work orders and work centers, and maintaining repair and maintenance of work orders.

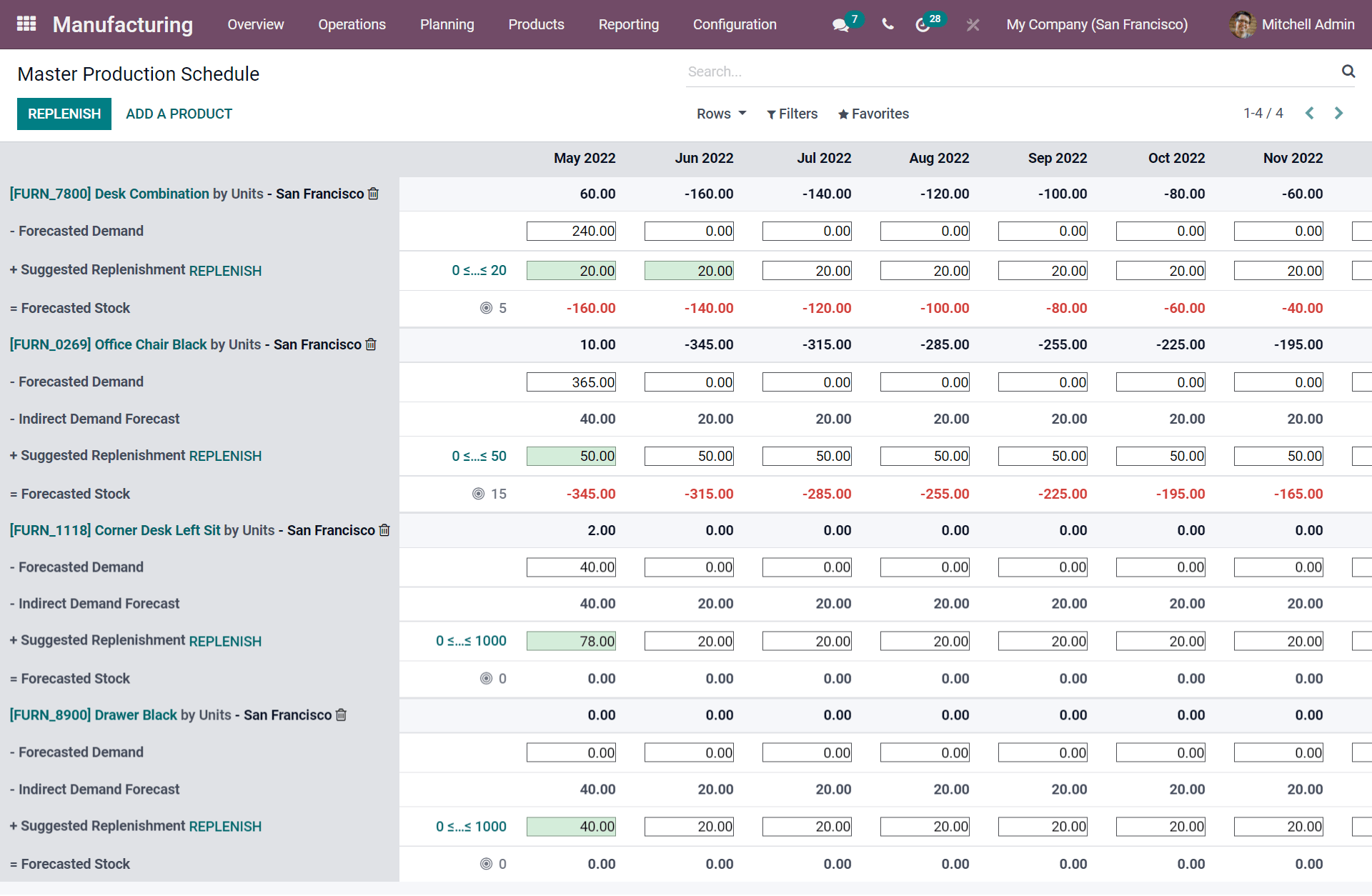

Odoo 15 also allows for the scheduling and planning of manufacturing orders. Furthermore, when production is taking place, the Odoo ERP is keeping track of machine maintenance and repair. To correctly manage devices, the manufacturing module in Odoo -15 is connected with the maintenance module. With Odoo 15, it also reports and identifies the status of different types of machinery. Manufacturing procedures are typically carried out not just in a single location, but also in several locations. Manually managing all operations and planning may be tough, resulting in disruptions and numerous mistakes. As a result, Odoo can eliminate any mistakes and provide precise computations and reports in each work center.

This blog explains how to plan and manage your manufacturing firm with Odoo-V-15, as well as how to manage the work centers.

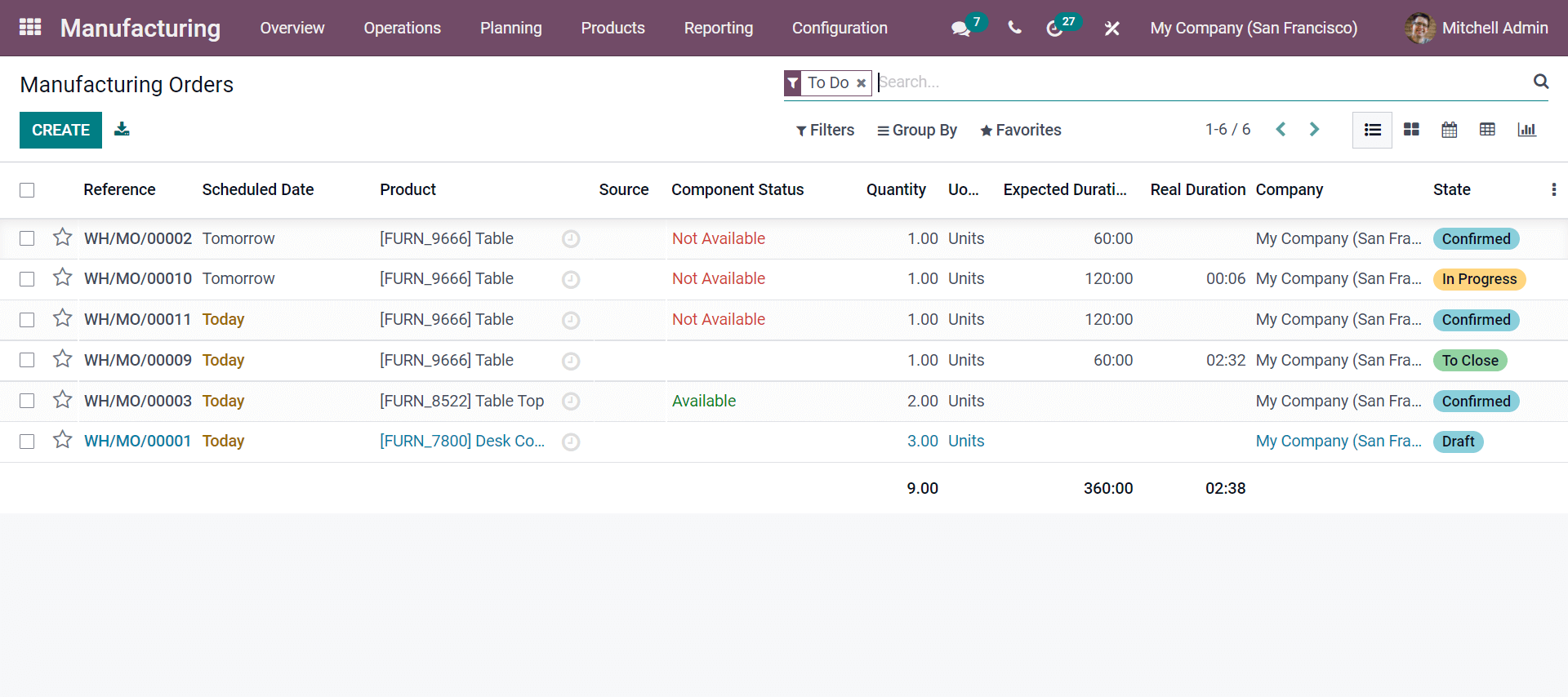

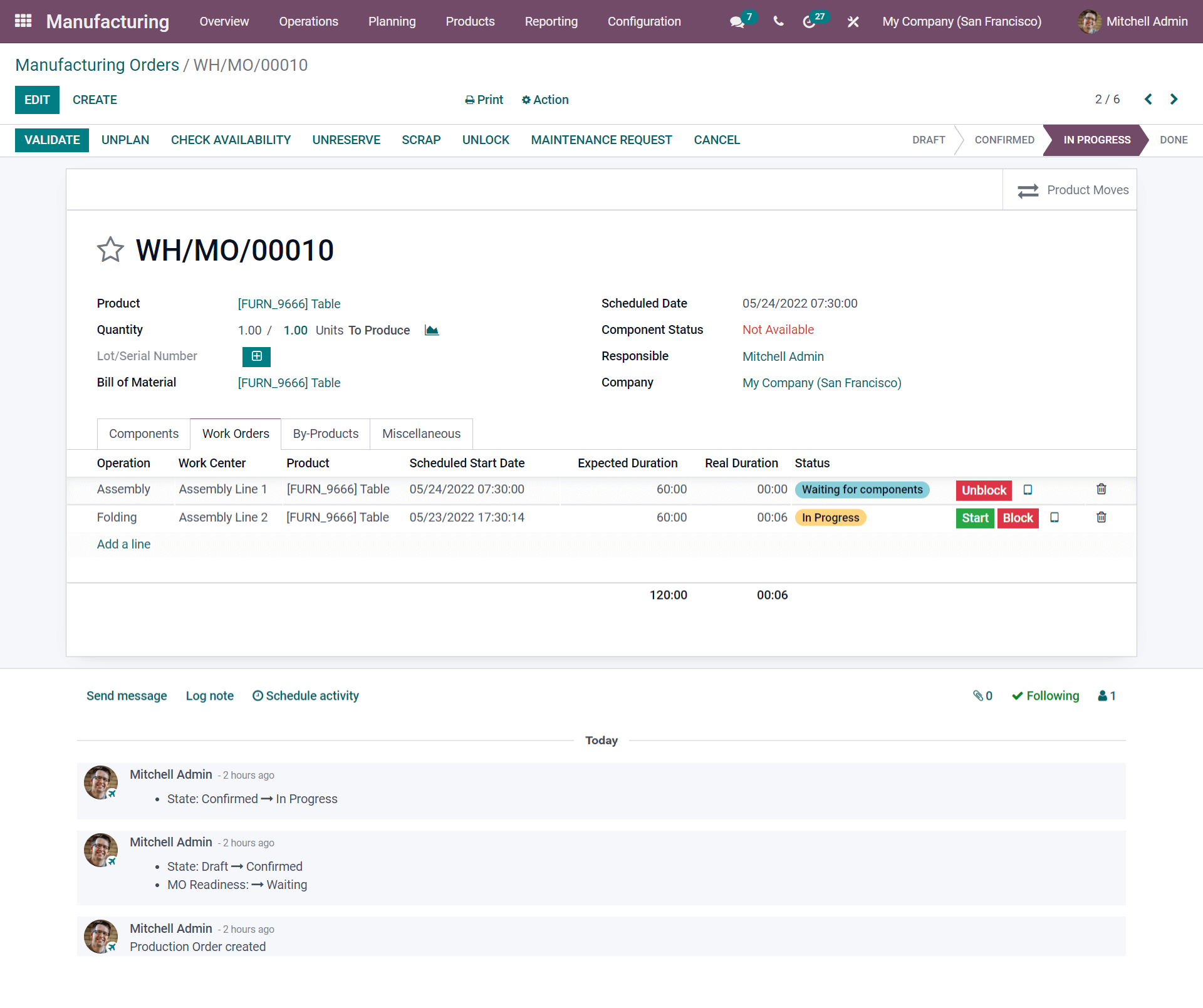

Production may be managed in Odoo 15 by creating a manufacturing order in the manufacturing module. Move the Manufacturing module>Operations>Manufacturing orders to explore how production is controlled

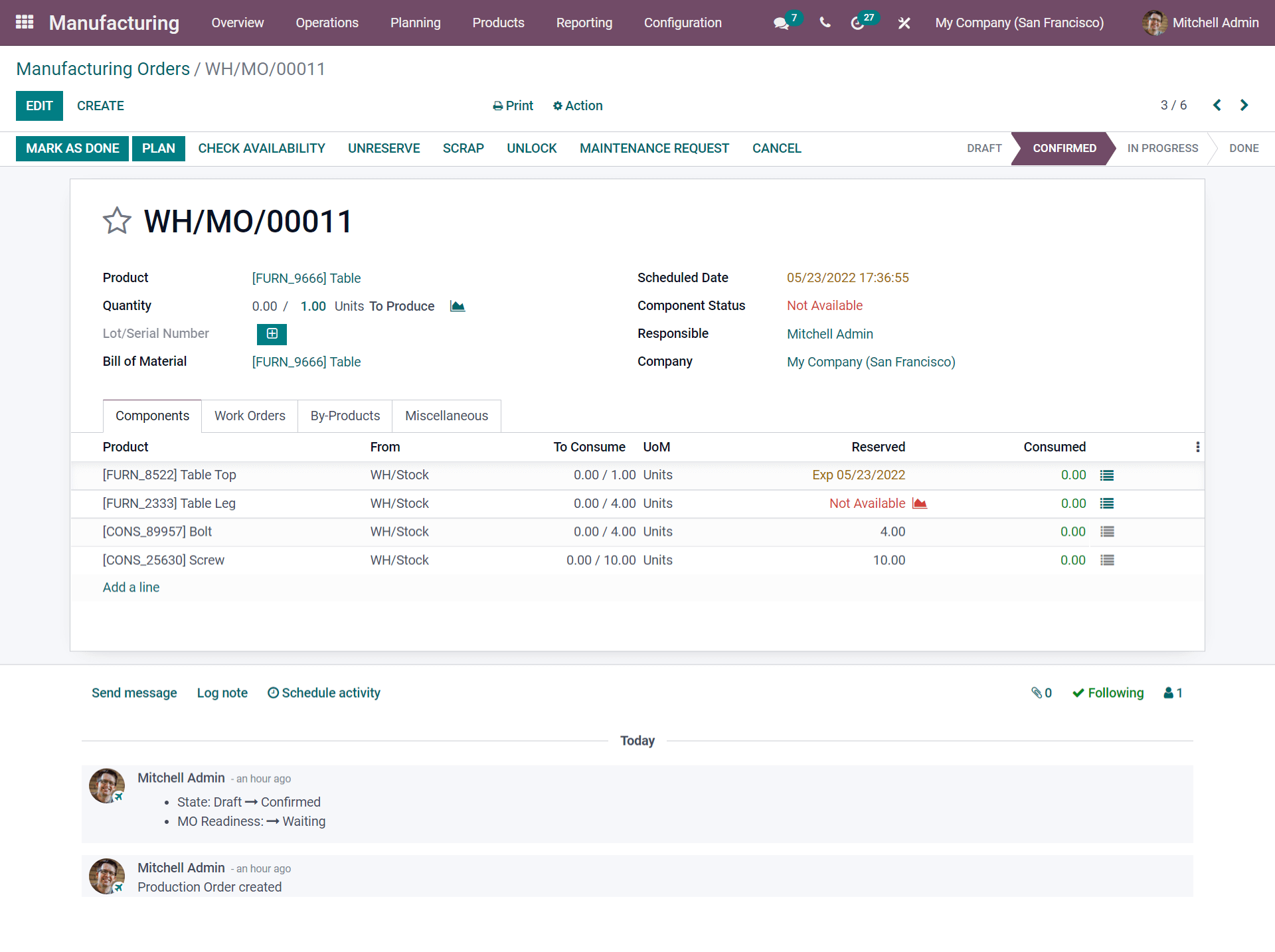

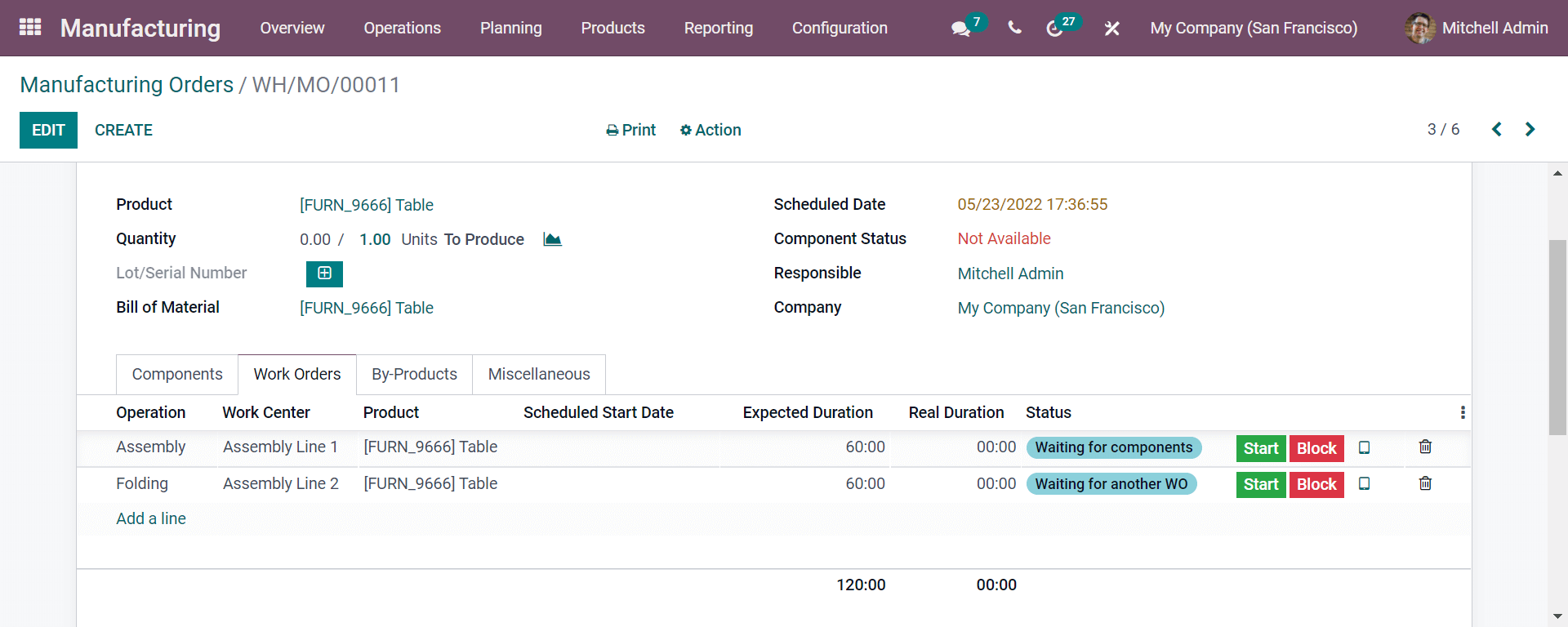

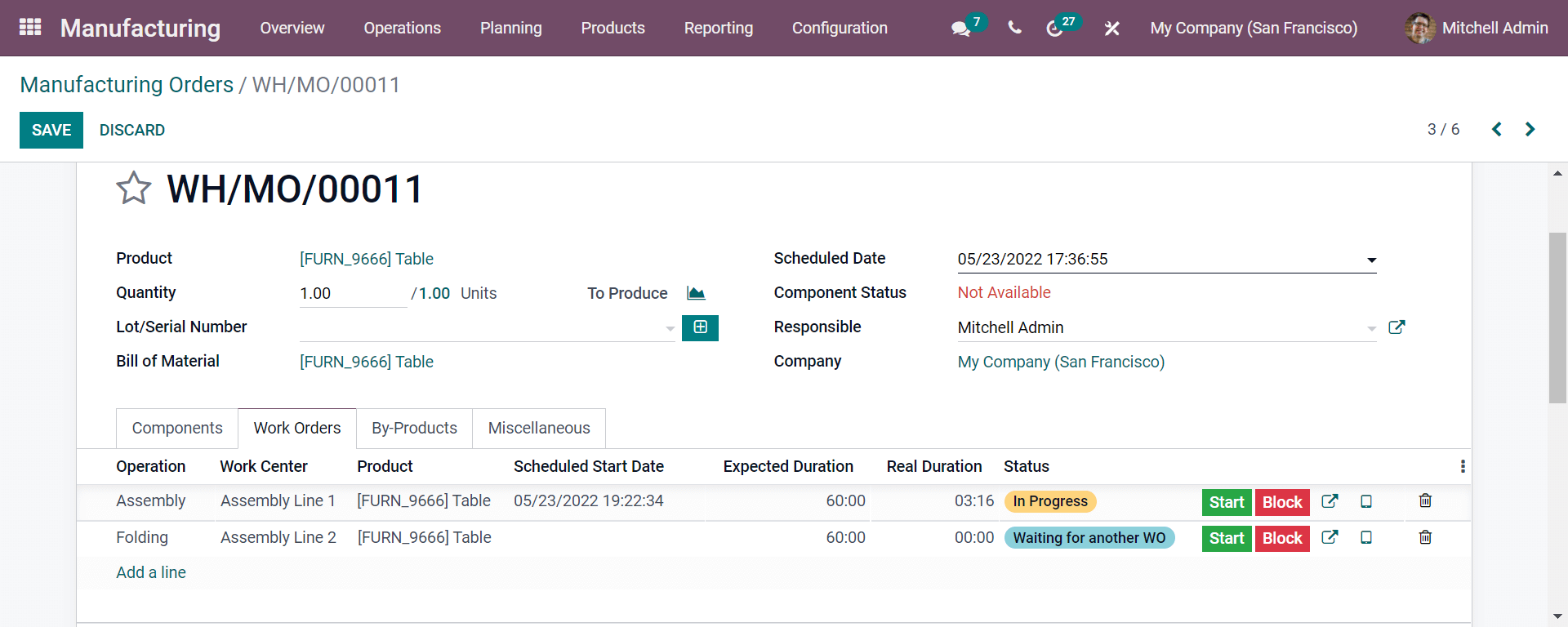

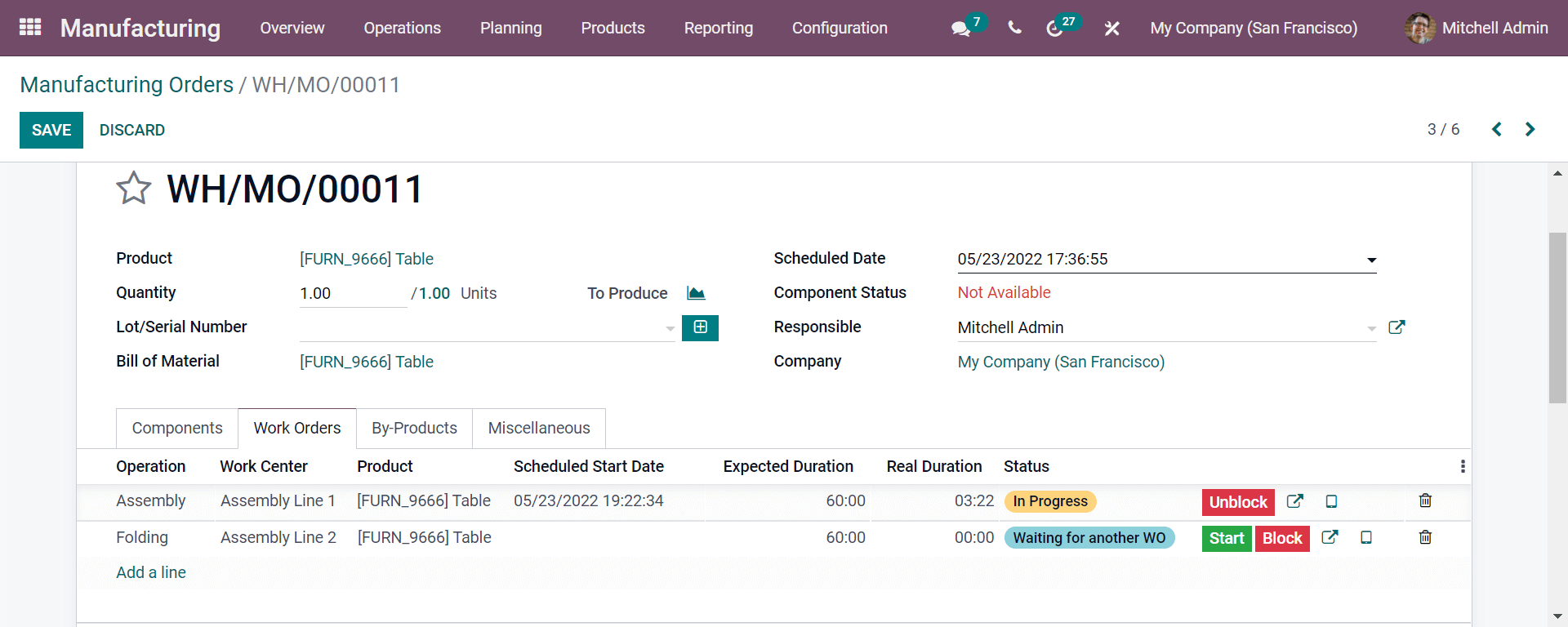

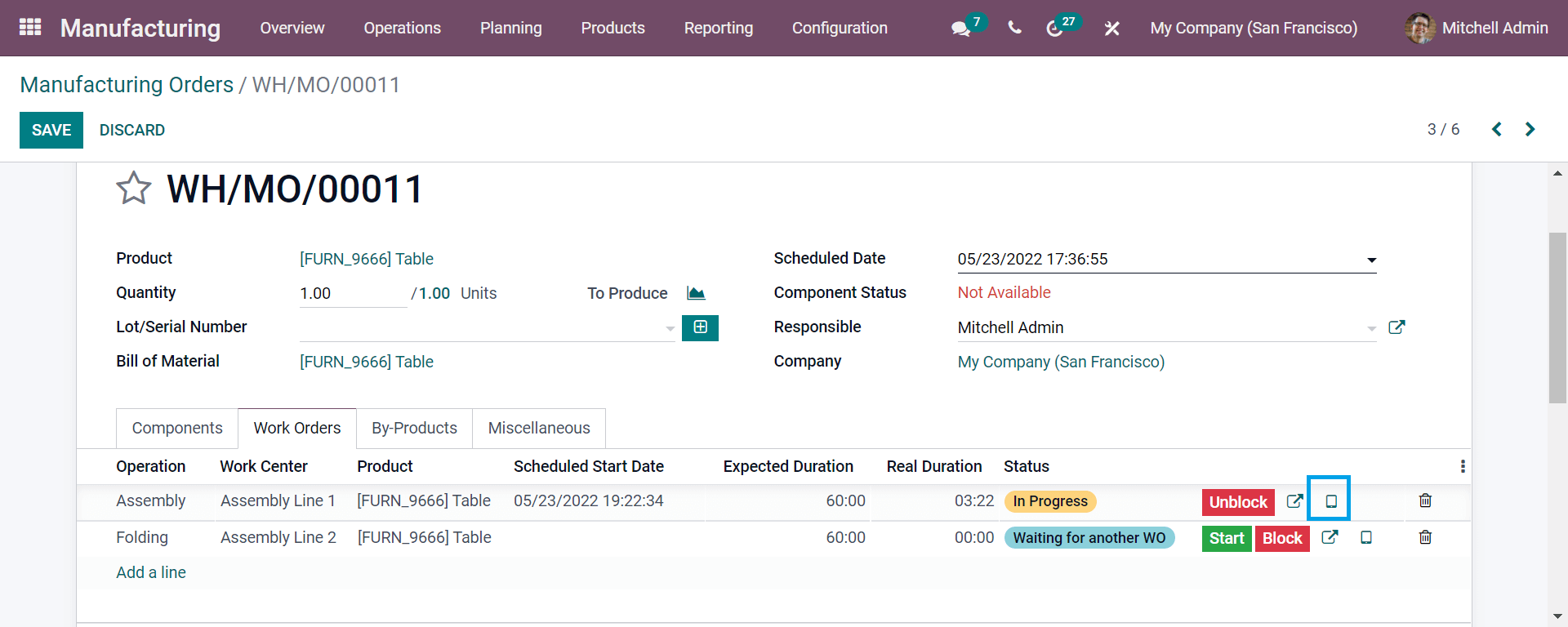

Now, access the work orders sub-tab in the manufacturing orders to check what's going on.

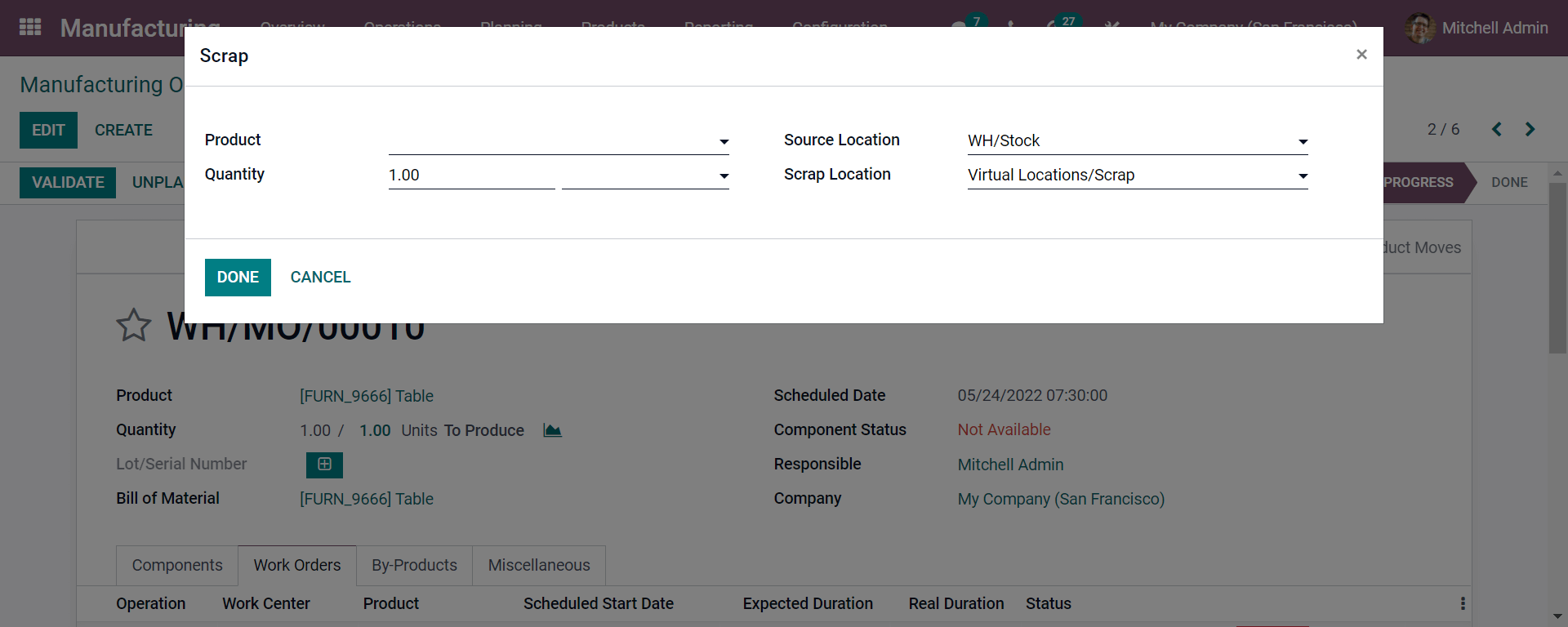

The user is redirected to a pop-up window when they click the Scrap button, as shown in the screenshot below.

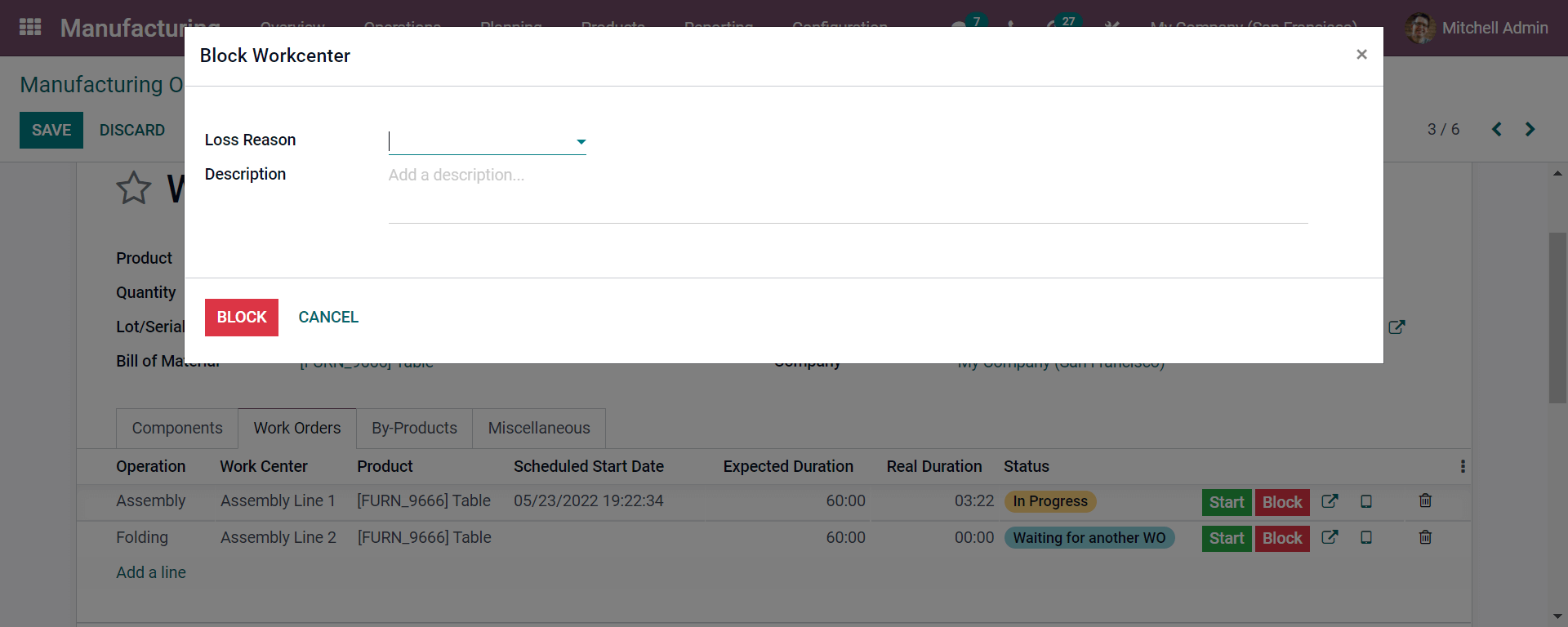

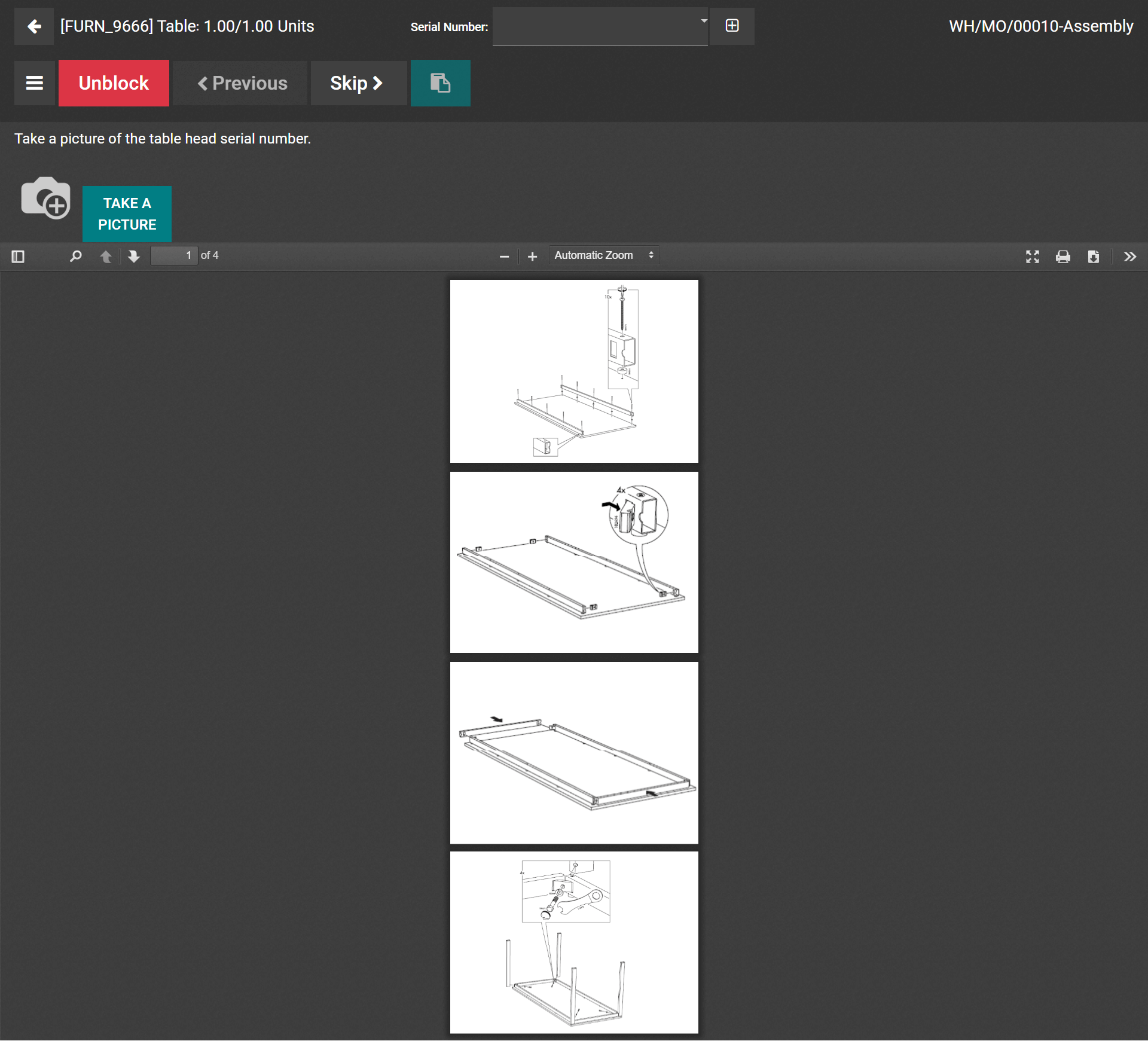

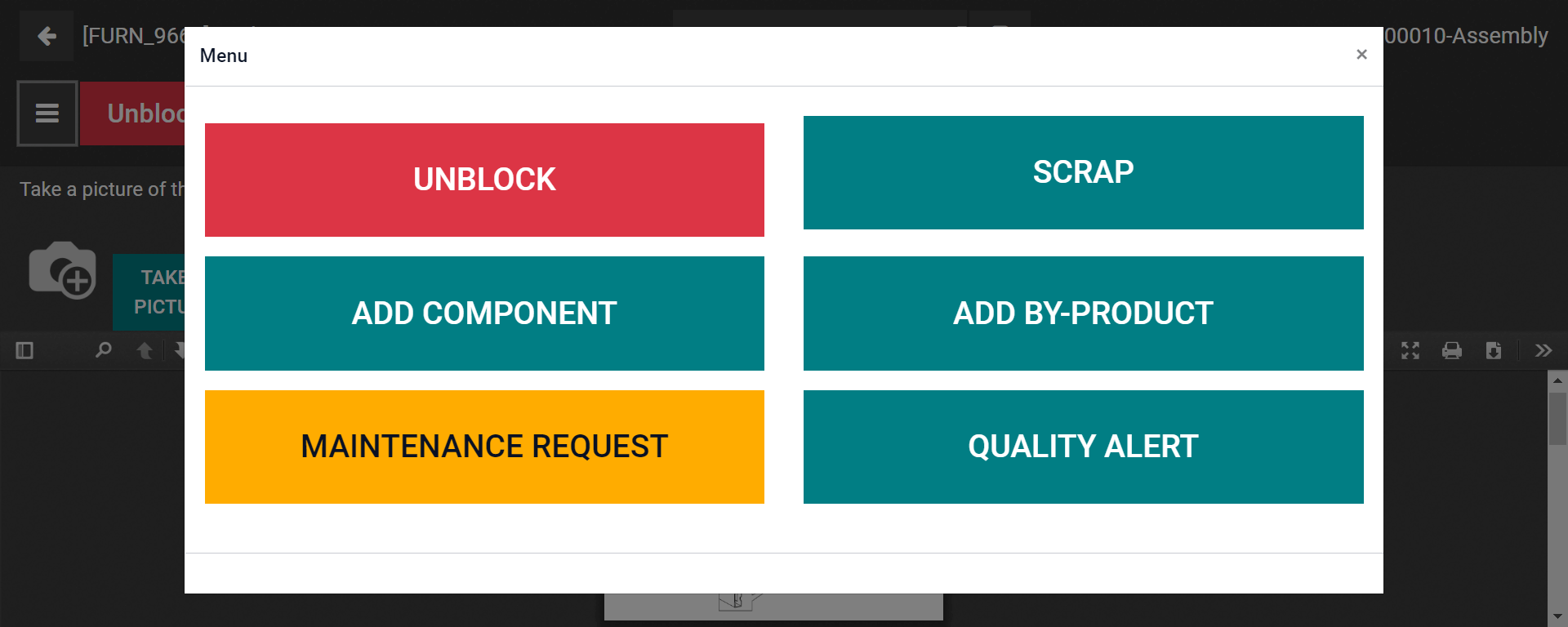

Let's have a look at what we get when we click on the icon.

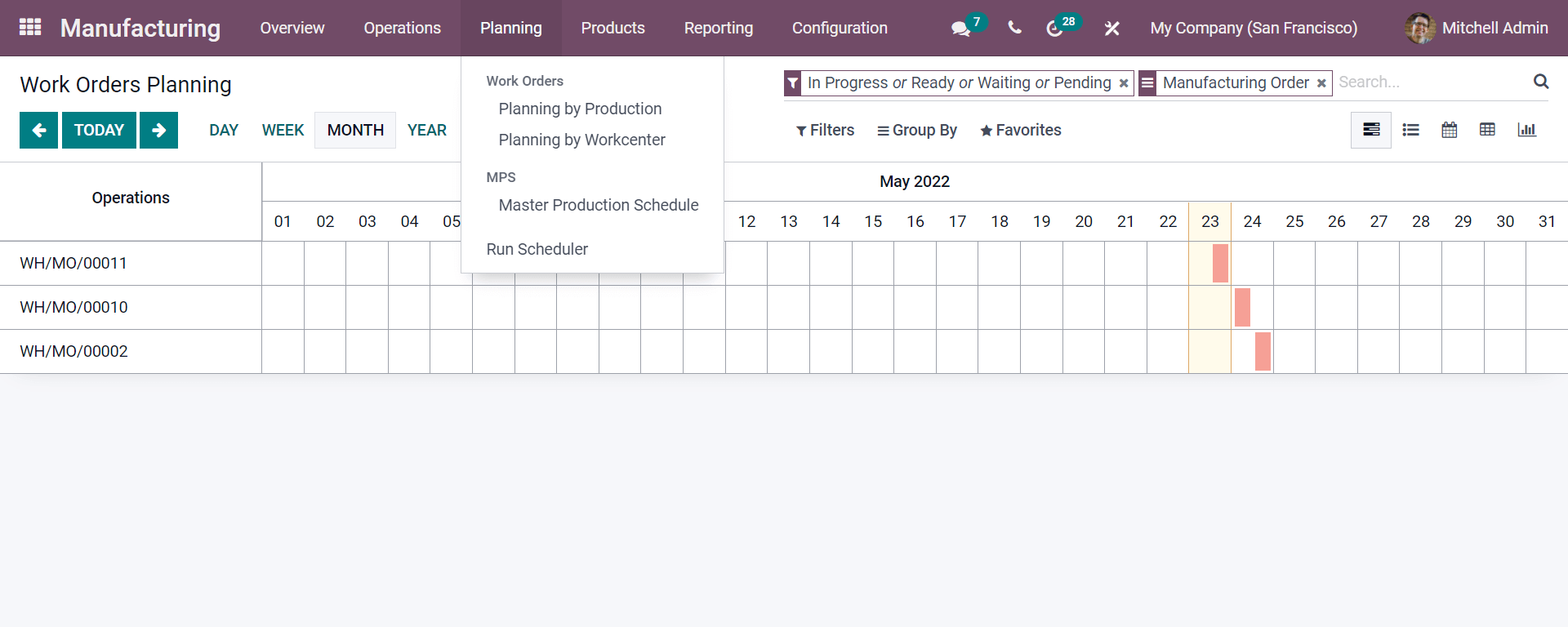

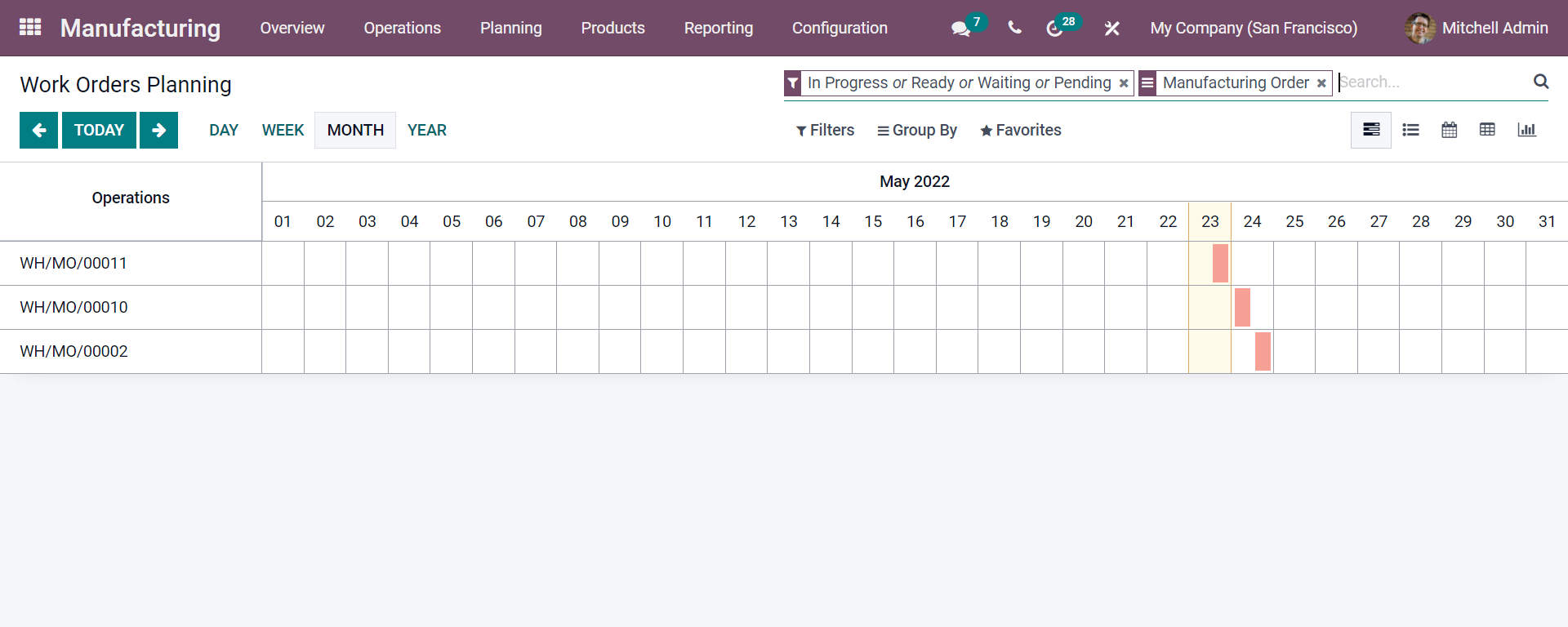

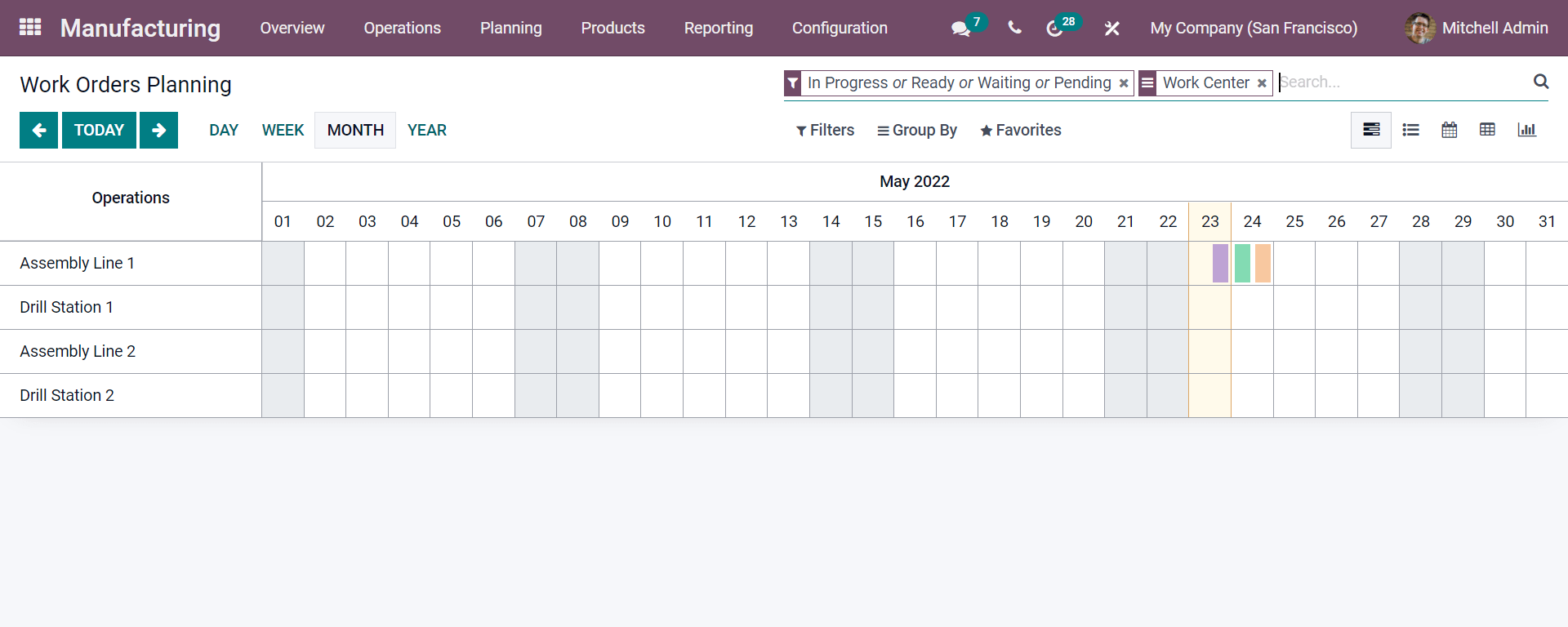

In Odoo 15, the user may also organize the actions that take place in the manufacturing company during this process.

Conclusion: Odoo 15 ERP To Manage Your Manufacturing Business

This brings the blog to a close, and the user may now properly plan and manage the production process while also running a successful business. The manufacturing module of Odoo 15 makes it easier to run your business and saves you time.

The Odoo Manufacturing ERP platform enables users to handle manufacturing complexities, handle material bills, plan manufacturing orders, monitor job orders, and much more.

The above list of techniques can be used for industry-specific ERP tools, as it provides you with successful Manufacturing precision for your business. At ERPCloud LLC, we provide you with one of the most common open source ERP applications, which includes modules such as manufacturing, sales, purchase, inventory, warehouse, MRP, and more.

If you're interested in learning more about Odoo and implementing it in your business, please contact us at sales@erpxcloud.com. Our dedicated team of Odoo experts is ready to customize and execute the best solutions for your business to ensure optimum success in terms of leads, sales, and revenue.

Visit our website at www.erpxcloud.com to get answers to your questions.

Odoo 15 ERP To Manage Your Manufacturing Business